- inCAD Library Home

- > No.000181 Measures for the thrust load of a small-size motor shaft

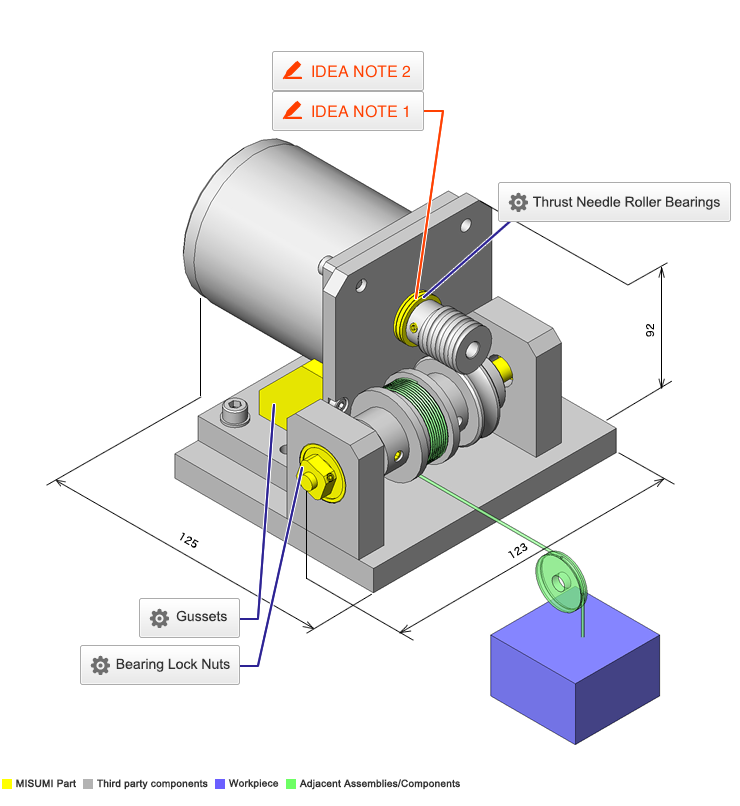

No.000181 Measures for the thrust load of a small-size motor shaft

29

29

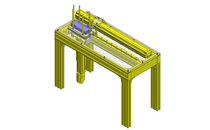

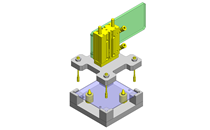

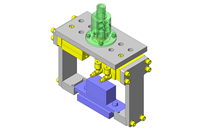

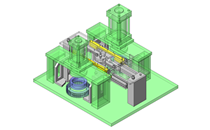

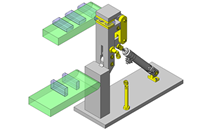

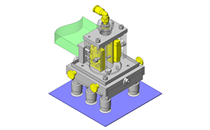

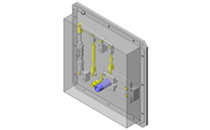

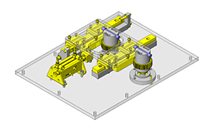

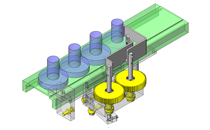

Reducing the thrust load without using a coupling

Related Category

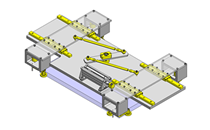

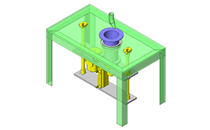

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

Purpose

- Purpose

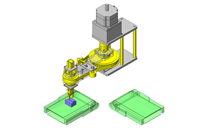

- Reducing the thrust load to the motor shaft without using coupling.

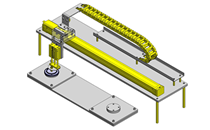

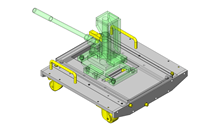

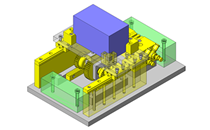

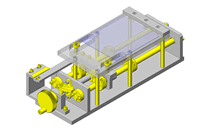

- Operation

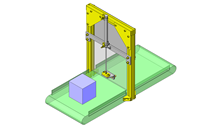

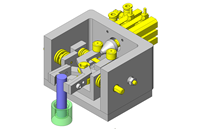

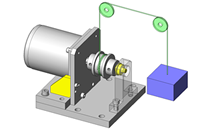

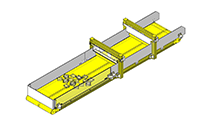

- Worm gear and wheel are rotated by the motor, and the drum on the shaft wind the wire.

Points for use

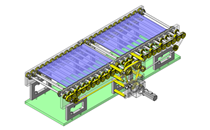

- Applicable to thrust load from one direction only.

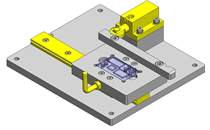

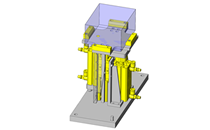

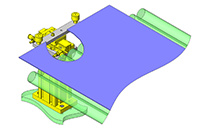

Target workpiece

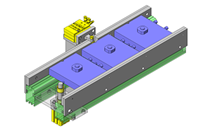

- Shape: Block

- Size: W40 x D40 x H25mm

- Weight: 0.3kg

Design Specifications

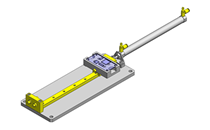

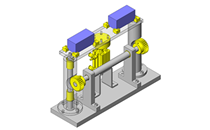

Operating Conditions or Design Requirements

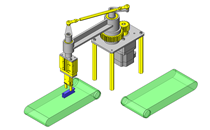

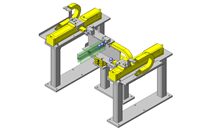

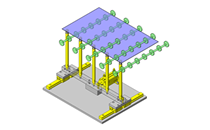

- Up and down stroke: 30mm

- External size: W123 x D125 x H92mm

Required Performance

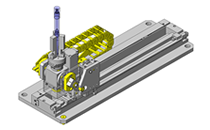

- Load: 3N

Selection Criteria for Main Components

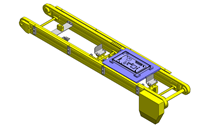

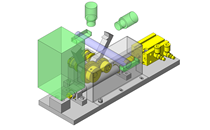

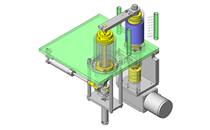

- A motor with thrust load of 0.8N is selected to pull up a workpiece of 0.3kg.

Design Evaluation

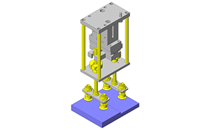

Verification of main components

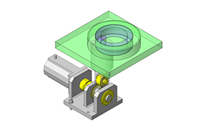

- Select the bearing to withstand the load weight.

- Thrust bearing selection

- Conditional values: Diameter of the wire winding part of the drum d1 = 28mm, pitch circle diameter of the worm wheel d2 = 30mm, motor rotational speed z1 = 1200rpm, workpiece mass W = 0.3kg, gravitational acceleration g = 9.8m/s², work movement length l1 = 30mm, friction coefficient on the tooth surface µ = 0.0167, tooth rectangular pressure angle a = 20°, worm gear advance angle y1 = 3.58°, pitch circle diameter of worm gear d3 = 16mm, worm gear rotational speed q1 = 1200mm, basic load rating of thrust bearing c1 = 6.8kN

- Number of revolution necessary for the drum to wind the workpiece n1 is given as follows:

n1 = d1 x π / l1 = 28 x π / 30 = 2.93

Motor rotation time at that time is given by

t1 = d2 x n1 x (60 x z1) = 30 x 2.93 x (60 x 1200) = 4.40t - Net power H1 applied to the worm gear is given by

H1 = W x g x l1 / t1 = 0.3 x 9.8 x 30 / 4.40 = 0.02N = 2.72 x 10-5 PS - Apparent friction angle on the tooth surface p1 is given by

p1 = tan - 1 (µ) = tan - 1 (0.0167) = 0.957° - Axial thrust load F1 of the worm gear is given by

F1 = F2 / tan (y + p) = 1.432 x H1 x 106 / {tan (y1 + p1) x d3 x q1} x g

= 1.432 x 2.72 x 10-5 x 106 / {tan (3.58 + 0.957) x 16 x 1200} x 9.8

= 0.25N < 6.8kN = c1

⇒No problem

Other Design Consideration

- The bearing, instead of bush, is used although operation turns into low speed rotation because of the worm gear and wheel drive.

- Mounting should be conducted so that no gap exists between the motor bracket, bearing, and the worm gear.

Explore Similar Application Examples

Page

-

/

-