- inCAD Library Home

- > No.000139 Workpiece Clamp Station

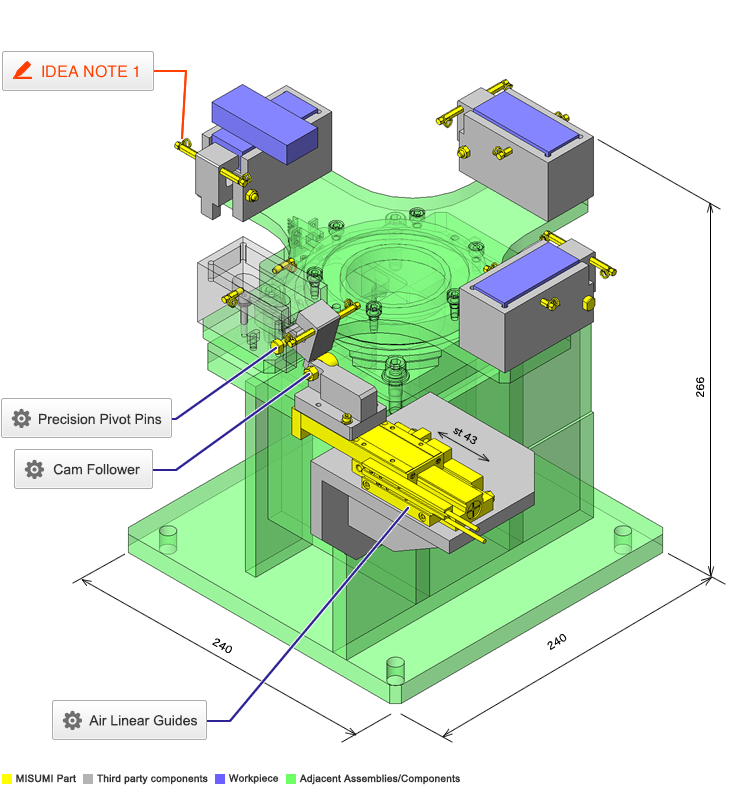

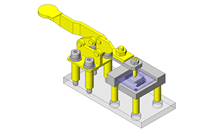

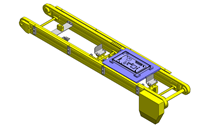

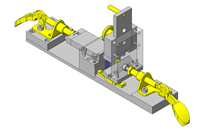

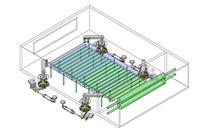

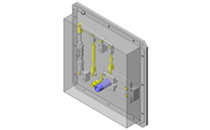

No.000139 Workpiece Clamp Station

14

14

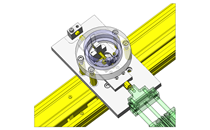

Clamp mechanisms operated by pneumatic linear actuator.

Related Category

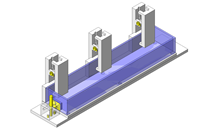

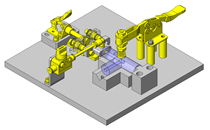

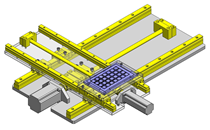

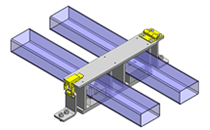

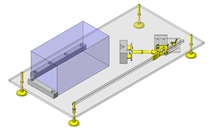

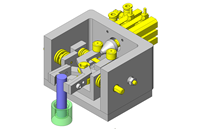

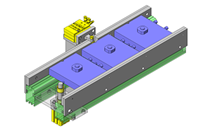

- * Unit assembly CAD data consists of some sub-assemblies.

Each sub-assembly unit can be used as it is or can be edited.

Application Overview

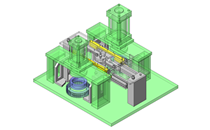

Purpose

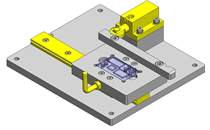

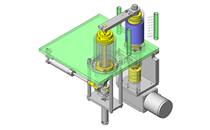

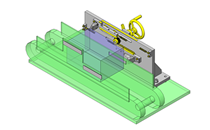

- A cylinder employing an automatic mechanism unclamps the workpiece as the pusher mounted on the cylinder presses against the hinge block..

- Clamps the workpiece via the tension springs attached to the work holder.

Points for use

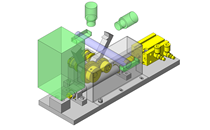

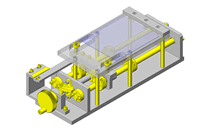

- The workpiece is suctioned and transferred to the charging/discharging position by another unit.

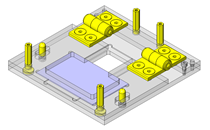

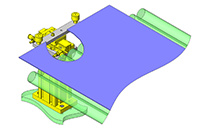

Target workpiece

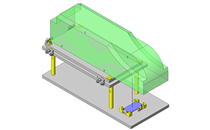

- Workpiece: resin case

Material:ABS

outer dimensions:66 x 27 x 15

Design Specifications

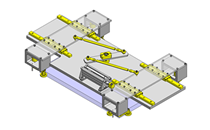

Operating Conditions or Design Requirements

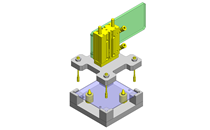

- Cylinder Stroke: 43mm

- Deflection of tension spring: 5mm

- Outer dimensions: W240 x D240 x H266 (overall dimensions)

Required Performance

- Cylinder thrust of 21N or higher

(Following the calculation process, a cylinder with a cylinder thrust with a safety factor 1.5 times the spring force was selected.) - Required clamping force: 10N

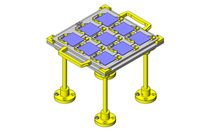

Selection criteria for Main Components

- Cylinder

- Stroke adjustment is easy and load requirement is satisfied.

Design Evaluation

Verification of main components

- A spring with the required clamping force was selected, and the cylinder for unclamping was selected according to the spring force.

- Load of tension spring

- Required clamping load: FA = 10N

- Spring deflection during clamping: x = 11mm

- Number of used springs: n = 2 pieces

- Spring initial tension: f = 1.67N

- FA = n (kx + f)

- From k = (FA / n - f) / x = (10 / 2 - 1.67) / 11 = 0.30,

- Spring constant: k = 0.32N/mm was selected.

- Cylinder thrust

- Spring force during unclamping: FB

- Spring deflection during unclamping: d = 16mm

- FB = n (kd + f)

- = 2 x (0.32 x 16 + 1.67)= 13.58N

- If safety factor is set to 1.5, 13.58 x 1.5 ≈ 20.37N.

- When cylinder thrust P > FB, the specification is satisfied.

Other Design Consideration

- As the workpiece needs to be held while it is transferred by a turn table (another unit), the mechanism keeps clamping the workpiece using a spring.

- The pusher (cylinder) stands by at the unclamp position and the turn table (another unit) transfers the workpiece to the unclamp position.

Explore Similar Application Examples

Page

-

/

-