Tłumaczymy nasz sklep na język polski!

- Tip Shape

- Material

- Steel

- EN 1.1191 Equiv.

- Stainless Steel

- EN 1.4037 Equiv.

- EN 1.4301 Equiv.

- Hardness

- Large Head/Small Head

- B(mm)[5–25/1mm jedn.]

- F(mm)[0.3–14/0.1mm jedn.]

- P(mm)[4–30/0.01mm jedn.]

- S(mm)[3–29/0.01mm jedn.]

- V(mm)[3–29/0.1mm jedn.]

- W(mm)[1–28.5/0.5mm jedn.]

- CAD

- 2D

- 3D

- Szacowane dni wysyłki

- Wszystko

- W ciągu 9 dni robocze

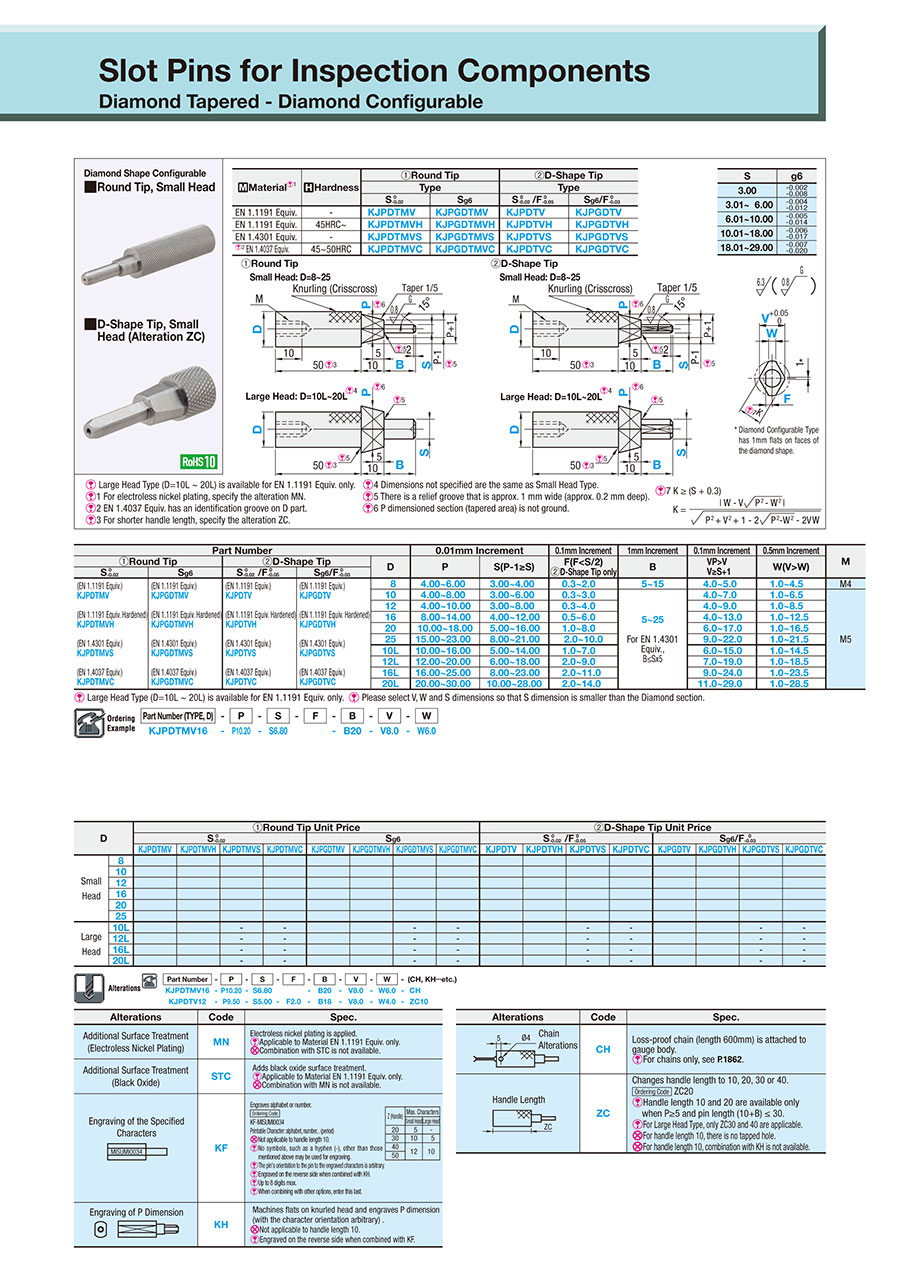

Slot Pins for Inspection Jigs / Stepped Diamond / Tapered / Configurable(Lista numerów części: str. 2)

Umieść kursor myszy nad ilustracją, aby ją powiększyć

Numer części:

.Rysunek konturowy i tabela specyfikacji

(1) Round tip type

Small Head: D = 8 to 25

(2) Tip cut type

Small Head: D = 8 to 25

Large Head: D = 10 L to 20 L" ! "4

Large Head: D = 10 L to 20 L" ! "4

* Diamond Configurable Type has

1 mm flats on faces of the diamond shape.

[ ! ]3

[ ! ]6

[ ! ]5

[ ! ]5

[ ! ]3

[ ! ]3

[ ! ]6

[ ! ]5

[ ! ]6

[ ! ]5

[ ! ]5

[ ! ]3

[ ! ]5

[ ! ]5

[ ! ]6

[ ! ]5

[ ! ]7

[ ! ] 2. EN 1.4125 Equiv. or 13Cr stainless steel has an identification groove on D part.

[ ! ] 3. For shorter handle length, specify the alteration ZC.

[ ! ] 4. Dimensions not specified are the same as those of Small Head Type.

[ ! ] 5. There is a relief groove that is approx. 1 mm wide (approx. 0.2 mm deep).

[ ! ] 6. P dimension section (tapered part) is not ground.

[ ! ]7 K ≥ (S+0.3)

[!] This product is hardened for the entire part.

[!] Unless otherwise specified, the dimension tolerance conforms to JIS B 0405 Class m. However, tapped depth, and angular dimension tolerances are excluded.

| [M]Material [!] 1 | [H] Hardness | (1) Round tip type | (2) Tip cut type | ||

| TYPE | TYPE | ||||

| S 0 −0.02 | Sg6 | S 0 −0.02/F 0 −0.05 | Sg6/F 0 −0.03 | ||

| EN 1.1191 Equiv. | - | KJPDTMV | KJPGDTMV | KJPDTV | KJPGDTV |

| EN 1.1191 Equiv. | 45HRC or more | KJPDTMVH | KJPGDTMVH | KJPDTVH | KJPGDTVH |

| EN 1.4301 Equiv. | - | KJPDTMVS | KJPGDTMVS | KJPDTVS | KJPGDTVS |

| [ ! ] 2 EN 1.4125 Equiv. or 13Cr Stainless Steel | 45 to 50HRC | KJPDTMVC | KJPGDTMVC | KJPDTVC | KJPGDTVC |

Specification Table

| Part Number (TYPE·D) | — | P | — | S | — | F | — | B | — | V | — | W |

| KJPDTMV16 | — | P10.20 | — | S6.80 | — | B20 | — | V8.0 | — | W6.0 |

| S | g6 |

| 3.00 | −0.002 −0.008 |

| 3.01 to 6.00 | −0.004 −0.012 |

| 6.01 to 10.00 | −0.005 −0.014 |

| 10.01 to 18.00 | −0.006 −0.017 |

| 18.01 to 29.00 | −0.007 −0.020 |

| Part Number | 0.01 mm Increments | 0.1 mm Increments | 1 mm Increments | 0.1 mm Increments | 0.5 mm Increments | M (Coarse) | |||||

| (1) Round tip type | (2) Tip cut type | D | P | S (P−1 ≥ S) | F (F < S/2) (2) Tip cut type only | B | V (P > V,V ≥ S+1) | W (V > W) | |||

| S 0 −0.02 | Sg6 | S 0 −0.02/F 0 −0.05 | Sg6/F 0 −0.03 | ||||||||

| (EN 1.1191 Equiv.) KJPDTMV (EN 1.1191 Equiv. (hardened)) KJPDTMVH (EN 1.4301 Equiv.) KJPDTMVS (EN 1.4125 Equiv. or 13Cr Stainless Steel) KJPDTMVC | (EN 1.1191 Equiv.) KJPGDTMV (EN 1.1191 Equiv. (hardened)) KJPGDTMVH (EN 1.4301 Equiv.) KJPGDTMVS (EN 1.4125 Equiv. or 13Cr Stainless Steel) KJPGDTMVC | (EN 1.1191 Equiv.) KJPDTV (EN 1.1191 Equiv. (hardened)) KJPDTVH (EN 1.4301 Equiv.) KJPDTVS (EN 1.4125 Equiv. or 13Cr Stainless Steel) KJPDTVC | (EN 1.1191 Equiv.) KJPGDTV (EN 1.1191 Equiv. (hardened)) KJPGDTVH (EN 1.4301 Equiv.) KJPGDTVS (EN 1.4125 Equiv. or 13Cr Stainless Steel) KJPGDTVC | 8 | 4.00 to 6.00 | 3.00 to 4.00 | 0.3 to 2.0 | 5 to 15 | 4.0 to 5.0 | 1.0 to 4.5 | M4 |

| 10 | 4.00 to 8.00 | 3.00 to 6.00 | 0.3 to 3.0 | 5 to 25 For EN 1.4301 Equiv. B ≤ S × 5 | 4.0 to 7.0 | 1.0 to 6.5 | M5 | ||||

| 12 | 4.00 to 10.00 | 3.00 to 8.00 | 0.3 to 4.0 | 4.0 to 9.0 | 1.0 to 8.5 | ||||||

| 16 | 8.00 to 14.00 | 4.00 to 12.00 | 0.5 to 6.0 | 4.0 to 13.0 | 1.0 to 12.5 | ||||||

| 20 | 10.00 to 18.00 | 5.00 to 16.00 | 1.0 to 8.0 | 6.0 to 17.0 | 1.0 to 16.5 | ||||||

| 25 | 15.00 to 23.00 | 8.00 to 21.00 | 2.0 to 10.0 | 9.0 to 22.0 | 1.0 to 21.5 | ||||||

| 10 L | 10.00 to 16.00 | 5.00 to 14.00 | 1.0 to 7.0 | 6.0 to 15.0 | 1.0 to 14.5 | ||||||

| 12 L | 12.00 to 20.00 | 6.00 to 18.00 | 2.0 to 9.0 | 7.0 to 19.0 | 1.0 to 18.5 | ||||||

| 16 L | 16.00 to 25.00 | 8.00 to 23.00 | 2.0 to 11.0 | 9.0 to 24.0 | 1.0 to 23.5 | ||||||

| 20 L | 20.00 to 30.00 | 10.00 to 28.00 | 2.0 to 14.0 | 11.0 to 29.0 | 1.0 to 28.5 | ||||||

Alterations

| Part Number | — | P | — | S | — | F | — | B | — | V | — | W | — | (CH·KH ... etc.) |

| KJPDTMV16 | — | P10.20 | — | S6.80 | — | B20 | — | V8.0 | — | W6.0 | — | CH | ||

| KJPDTV12 | — | P9.50 | — | S5.00 | — | F2.0 | — | B18 | — | V8.0 | — | W4.0 | — | ZC10 |

| Alterations | Code | Spec. | |||||||||||||||

| Additional Surface Treatment (Electroless Nickel Plating) | MN | Electroless nickel plating is applied. [ ! ] Applicable to Material EN 1.1191 Equiv. only [ NG ] Combination with STC is not available. | |||||||||||||||

| Additional Surface Treatment (Black Oxide) | STC | Adds black oxide surface treatment. [ ! ] Applicable to Material EN 1.1191 Equiv. only [ NG ] Combination with MN is not available. | |||||||||||||||

Engraving of the Specified Characters | KF | Engraves alphabet or number. Ordering Code KF−MISUMI0034 Printable Character: alphabet, number, . (period) [ NG ] Not applicable to handle length 10 [ ! ] No symbols, such as a hyphen (-), other than those mentioned above may be used for engraving.

[ ! ] Engraved on the reverse side when combined with KH. [ ! ] Up to 8 digits max. [ ! ] When combining with other options, enter this last. | |||||||||||||||

Engraving of P Dimension | KH | Machines flats on knurled head and engraves P dimension. (With the character orientation arbitrary). [ NG ] Not applicable to handle length 10 [ ! ] Engraved on the reverse side when combined with KF. | |||||||||||||||

| Alterations | Code | Spec. |

Chain | CH | Loss-proof chain (length 600 mm) is attached to gauge body. |

Handle Length | ZC | Changes handle length to 10, 20, 30 or 40. Ordering Code ZC20 [ ! ] Handle length 10 and 20 are available only when P ≥ 5 and pin length (10 + B) ≤ 30. [ ! ] For Large Head Type, only ZC30 and 40 are applicable. [ NG ] For handle length 10, there is no tapped hole. [ NG ] For handle length 10, combination with KH is not available. |

No Relief Groove | NMN | Omits the relief groove between knurled part and straight part on the step. [ NG ] Not applicable to Large Head Type |

KF Alteration (Engraving of Specified Characters) Precautions

(2) Printable characters are alphabets, numbers, and periods (.).

(3) Numbers can be up to 8 characters.

(4) When combining with other alterations, enter KF last.

(5) You cannot use more than 1 period (.).

[Example]

OK: KJPGSH16-P9.34-L30-STT-KH-KF-246625.5020

NG: KJPGSH16-P9.34-L30-STT-KH-KF-246625..5020

NG: KJPGSH16-P9.34-L30-STT-KH-KF-246.625.5020

Lista numerów części

| Numer części |

|---|

Cena jednostkowa (bez VAT)(Cena jednostkowa z podatkiem) | Standardowa data wysyłki |

|---|

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

Szczegółowe informacje

Podstawowe informacje

[Features] Tapered test pin that can set a diamond shape. -You can choose between 2 shapes.