Tłumaczymy nasz sklep na język polski!

Bite Hydraulic Pipe Fittings / Elbow / Threaded (KTGE6-2)

Umieść kursor myszy nad ilustracją, aby ją powiększyć

Przestroga

- All products come with a sleeve.

- Cena jednostkowa (bez VAT)

- 7.67 €

- Łącznie (bez VAT)

- 7.67 €Cena z VAT: 9.13 €

- Data wysyłki

- 5 dni roboczeReferencyjna data wysyłki: 03.07.2025

| Ilość | 1 - 9 | 10 - 284 | 285+ |

|---|---|---|---|

| Cena jednostkowa (bez VAT) (Cena jednostkowa z VAT) | 7.67 € (9.13 €) | 6.55 € (7.79 €) | 6.55 € (7.79 €) |

| Shipping days | 5 days | 5 days | Quote |

- * Informacje o dniach wysyłki, kosztach wysyłki i cenach.

Rysunek konturowy i tabela specyfikacji

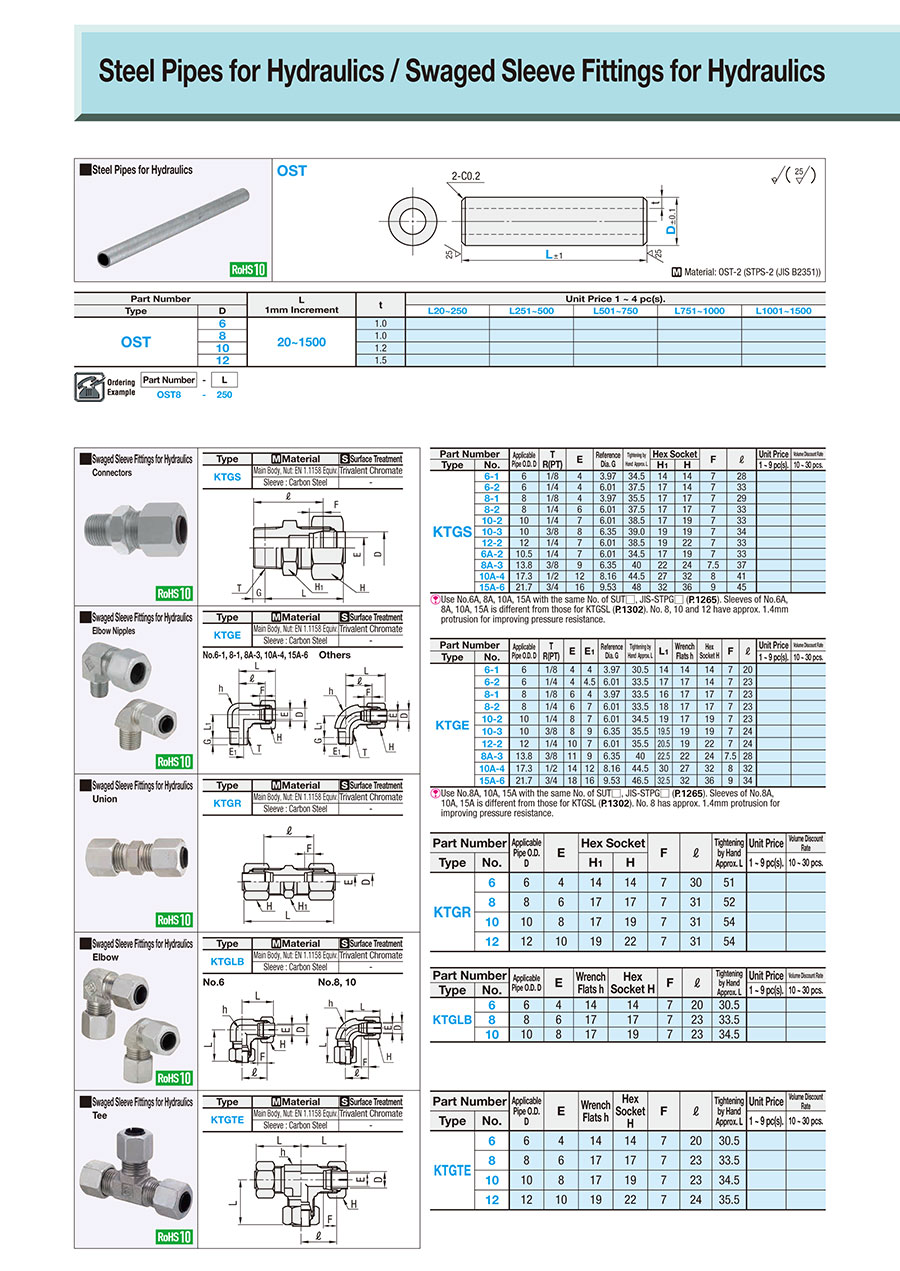

No.6-1 / 8-1 / 8 A-3 / 10 A-4 / 15 A-6

Others

| Type | [M] Material | [S] Surface Treatment |

| KTGE | Main Body‚ Nut: EN 1.1158 Equiv. | Trivalent Chromate |

| Sleeve: Carbon Steel | — |

Specification Table

| Part Number |

| KTGE10-2 |

| Part Number | Applicable Pipe O.D. D | T R (PT) | E | E1 | Reference Dia. G | Tightening by Hand Approx. L | L1 | Wrench Flats h | Hex Square Size H | F | ℓ | |

| Type | No. | |||||||||||

| KTGE | 6-1 | 6 | 1/8 | 4 | 4 | 3.97 | 30.5 | 14 | 14 | 14 | 7 | 20 |

| 6-2 | 6 | 1/4 | 4 | 4.5 | 6.01 | 33.5 | 17 | 17 | 14 | 7 | 23 | |

| 8-1 | 8 | 1/8 | 6 | 4 | 3.97 | 33.5 | 16 | 17 | 17 | 7 | 23 | |

| 8-2 | 8 | 1/4 | 6 | 6.5 | 6.01 | 33.5 | 18 | 17 | 17 | 7 | 23 | |

| 10-2 | 10 | 1/4 | 8 | 7.5 | 6.01 | 34.5 | 19 | 17 | 19 | 7 | 23 | |

| 10-3 | 10 | 3/8 | 8 | 8.5 | 6.35 | 35.5 | 19.5 | 19 | 19 | 7 | 24 | |

| 12-2 | 12 | 1/4 | 10 | 7.5 | 6.01 | 35.5 | 20 | 19 | 22 | 7 | 24 | |

| 8 A-3 | 13.8 | 3/8 | 11 | 9 | 6.35 | 40 | 22.5 | 22 | 24 | 7.5 | 28 | |

| 10 A-4 | 17.3 | 1/2 | 14 | 12 | 8.16 | 45 | 30 | 27 | 32 | 8 | 32 | |

| 15 A-6 | 21.7 | 3/4 | 18 | 16 | 9.53 | 47 | 32.5 | 32 | 36 | 9 | 34 | |

Sleeves of No.8 A, 10 A, 15 A is different from those for KTGSL.

No. 8 has approx. 1.4 mm protrusion for improving pressure resistance.

Features

- A joint that allows you to connect pipes simply by tightening the nut when there is no space for piping work or welding is not possible. It is an excellent product that completes the piping work by inserting the pipe or tube into the nut and tightening it.

- After temporarily tightening, attach it to the main body, and when you tighten the swaging sleeve nut, tighten it another 3/4 to 1 turn from the point where it suddenly feels tackier, and the tightening work is complete.

Structure/Tightening Procedure

Swaged Sleeve Fittings are composed of a main body, a sleeve and a nut.

[Tightening Procedure]

For utilizing performance of Swaged Sleeve Fittings for Steel Pipes, use of appropriate pipe and accurate tightening of fitting are required.

The following pre-tightening will make plumbing smooth and secure.

(1) Pre-tightening

- Insert the pipe with nut and sleeve inserted as shown in right figure into the fitting body. Make sure that pipe end contacts abutment part. Inadequate swaging due to the inadequate tightening may cause the pipe to pull out.

- Tighten the nut by hand.

- Tighten the nut with a wrench while rotating the pipe to the end of its rotation. Put a mark on this position of fitting body and the nut.

- Further tighten the nut by a wrench with1-1/4 turn at this mark.

- Loosen the nut once to see the state of the sleeve in order to confirm the following.

A: There is some millimeter distance between pipe end and sleeve end.

B: No substantial movement of the sleeve toward the direction of pipe axis is allowable. Moving toward circumferential direction is acceptable.

(2) Attach the pre-tightened pipe with

fitting body and tighten the nut by a wrench until you feel sudden resistance. Further tighten the nut by 1/4 turn, and tightening will be done.

[Disassembly/retightening]

- Can be disassembled just by loosening the nut. However, never tighten and loosen the nut while pressurized as it is very dangerous.

- 8 or more disassemblies and retightening are possible by following the Full Tightening Procedure as shown in (2).

[ ! ]Make sure that the tapered end of the sleeve is facing the fitting body.

If inserted backwards, pipe will not be properly swaged and may pull-off.

Szczegółowe informacje

Podstawowe informacje

[Features] A compression fitting suitable for hydraulic piping. -When working on piping where space is limited or welding is not possible, this fitting allows piping to be connected by simply tightening the nuts. -Simply insert a tube or hose into the nut and tighten to complete the piping work. -When the compression nut is tightened, tighten it further by 3/4 to 1 turn from the point where the reaction suddenly increases to complete the tightening process.

Przestroga

- All products come with a sleeve.