- [D] Outer Diameter(mm)

- 30

- 40

- 50

- 60

- 80

- Material (Base, Core)

- Steel

- EN 1.1191 Equiv.

- Aluminum

- Aluminum Alloy

- [L] Length (Range)(mm)

- I.D. d(mm)

- 8

- 10

- 12

- 15

- 20

- 25

- 30

- 35

- Surface Treatment

- L

- 100

- 150

- 200

- 300

- 400

- 500

- 600

- 700

- LC(mm)[50–690/1mm jedn.]

- CAD

- 2D

- 3D

Precision rollers

Numer części:

.Rysunek konturowy i tabela specyfikacji

Back to the Category Idler Rollers

Technical Drawing - Roller with Bearings

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More Information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Roller with Bearings

| Type | Material | Surface Treatment | O.D. Tolerance | Run-out | Perpendicularity | Circularity | ||

| 100~500mm | 600~700mm | 100~500mm | 600~700mm | |||||

| RORSPM | EN 1.1191 Equiv. | Electroless Nickel Plating | h7 | 5/100 | 0.1 | 5/100 | 0.1 | 5/100 |

| RORSPA | Aluminum Alloy | Clear Anodize | ||||||

Further specifications can be found under the tab More Information.

Composition of a Product Code - Roller with Bearings

| Part Number | - | d | - | L |

| RORSPM50 | - | 12 | - | L300 |

Alterations - Roller with Bearings

General Information - Roller with Bearings

Selection details of roller bearings

- Core material: aluminum, steel, stainless steel, plastic (POM, UHMWPE, polypropylene, MC nylon)

- Coatings: uncoated, burnished, nickel-plated, anodized

- Material surface: uncoated, polyurethane, antistatic polyurethane, heat-resistant polyurethane (~110°C), polyurethane foam, chloroprene rubber foam, silicone rubber, silicone rubber, nitrile rubber (NBR)

- Hardness: Shore A25, Shore A50, Shore A65, Shore A70, Shore A90, Shore A95

- Surface shape: cylindrical, spherical, groove (split running surface), flange on both sides, knurled

- Roller mounting: through hole, ball bearing, plain bearing bushing, threaded pin clamping, keyway, with axle shaft, lateral through holes

- Bearing material: steel, stainless steel

- Inner diameter: 3 to 40 mm

- Outer diameter: 8 to 100 mm

- Length: 50 to 1000 mm

Description/Basics

The range of applications for roller bearings is diverse in the industry. Basically, the roller bearing is used in mechanical engineering and system engineering for the transport of different objects and workpieces. They are often found in roller conveyors and the conveyance or return of fine films in the packaging industry (packaging).

MISUMI offers different roller bearing surfaces depending on the type of material being conveyed and the application. Whether a gentle rubberized roller bearing for sensitive goods has to be transported, a metal roller, or a massive roller bearing for heavy loads, the MISUMI online shop offers the appropriate roller bearing for almost any application and environmental influences.

A rubberized roller bearing can be equipped with different elastomers to withstand the requirements and influences. These can have different properties such as oil resistance, weather resistance or chemical resistance. MISUMI also offers a rubberized roller bearing with heat-resistant polyurethane (PUR) for higher temperatures.

MISUMI offers an antistatic roller bearing made of polyurethane for transporting electronic components that must be protected against static discharge via the option [UDC].Our roller bearings with foam are a special feature. Compared to conventional foams, the roller bearing with polyurethane foam has a low absorption of water, oil and chemicals. This is made possible by the closed pores of the foam. Another significant advantage of combining a roller bearing with polyurethane foam is the vibration-damping properties of the foam. Roller bearings with foam are also suitable for transporting thinner materials.

A roller bearing with chloroprene rubber foam is particularly low-return and has a high resistance to weather, aging, ozone, heat and cold. This makes it a very balanced foam that is often used in the general industry.

In addition to the materials of the tread, different geometries are also available for various purposes.

Cylindrical roller bearings are often used for roller conveyors or roller carriers.

Balled roller bearings, on the other hand, are often used in conveyor belts in combination with flat belts. The spherical shape of the roller bearing can help align the transport belt in the centre. For flat belts with guide grooves, we offer special flat belt drive wheels that centre the belt more precisely.

Cylindrical roller bearings are often used in roller conveyors or roller carriers. Balled roller bearings are on the other hand often used in conveyor belts in combination with flat belts. The balled shape of the roller bearing can help align the transport belt in the centre. For flat belts with guide grooves, we offer special flat belt drive wheels that centre the belt more precisely.

The roller bearings and metal rollers from MISUMI can be selected in numerous mounting options. In addition, MISUMI offers the roller bearing with clamping groove, plain bearing bushing, integrated axle, lateral mounting holes and keyway.

The roller bearing with keyway groove is particularly suitable in combination with a keyway and rotary axis as a driven roller bearing or conveyer roller. This PDF gives you the keyways tolerances. It is recommended selecting a keyway from MISUMI for the connection, since the tolerances are coordinated.

A roller bearing is often also used in combination with ball bearings. The load capacity depends on the bearing used. The roller bearings with ball bearings are characterized by good smoothness. You can find which bearing was used for the metal roller with ball bearing under the tab More Information.

Rollers with larger outer diameters can also be found under our pipe rollers.

Application Examples - Roller with Bearings

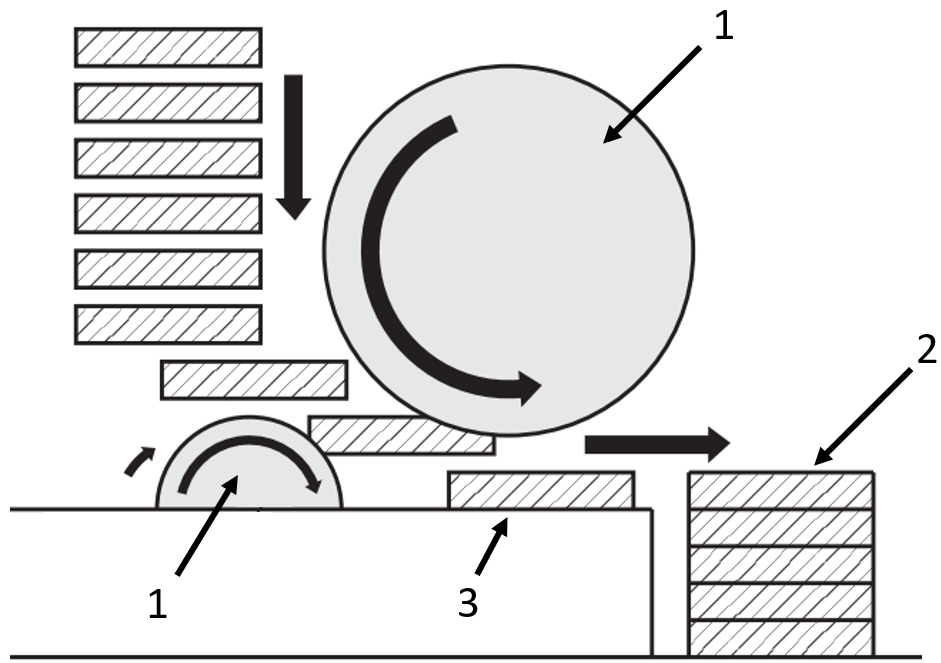

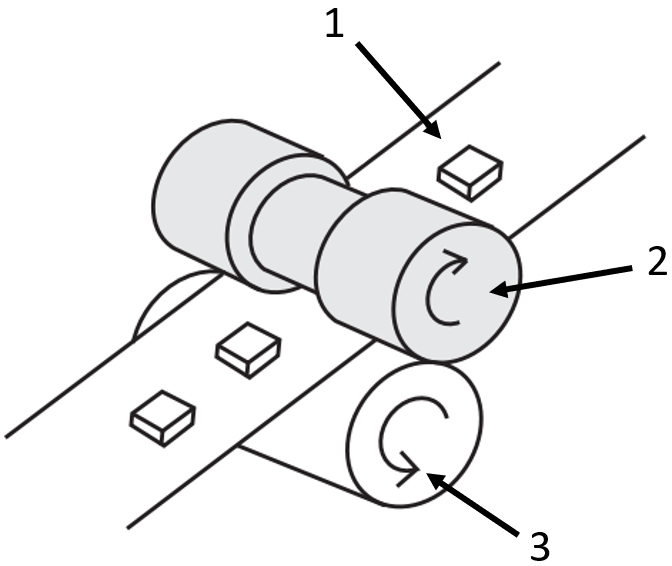

Application example: stack sorter

(1) Roller bearing rubberized, (2) workpiece, (3) plastic plate

Application example: belt conveyor

(1) Belt, (3) split roller bearing (groove), (3) roller bearing

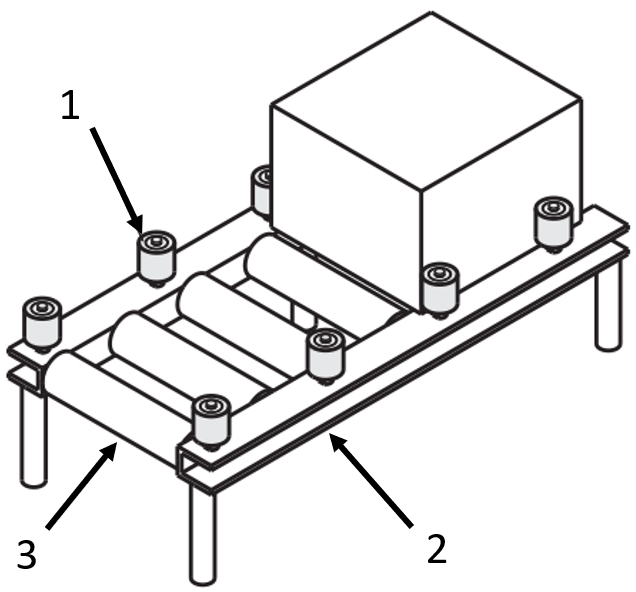

Application example roller conveyor

(1) Vertical guide rollers, (2) roller belt, (3) roller bearing

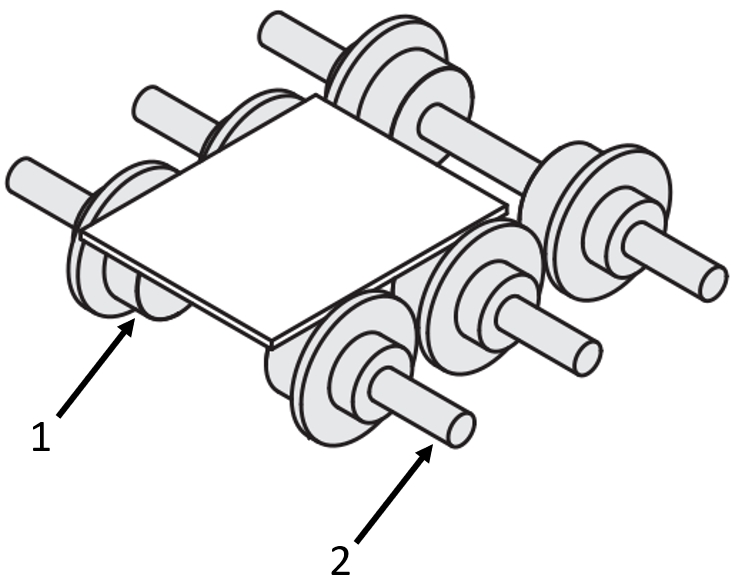

Application example: roller conveyor

(1) Plastic roller bearing, (2) rotary axes

Industrial Applications

Lista numerów części

| Numer części |

|---|

Cena jednostkowa (bez VAT)(Cena jednostkowa z podatkiem) | Standardowa data wysyłki |

|---|

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

- ( - ) | 9 dni robocze |

Szczegółowe informacje

Kontury i specyfikacja

Back to the Category Idler Rollers

Technical Drawing - Roller with Bearings

Open the technical drawing in the new window

Specification Tables - Roller with Bearings

| Part Number | d | L Selection | Bearing Used | d1 | D1 | B | ||||

| TYPE | D | d Tolerance | EN 1.1191 Equiv. | Aluminum | EN 1.1191 Equiv. | Aluminum Alloy | ||||

| RORSPM RORSPA | 30 | 0 -0.021 | 8 | 100 150 200 300 400 500 | 100 150 200 300 400 500 | B608ZZ | 15.8 | 15 | 22 | 7 |

| 10 | B6900ZZ | 22 | 6 | |||||||

| 12 | B6901ZZ | 24 | 6 | |||||||

| 40 | 0 -0.025 | 10 | B6000ZZ | 21 | 22 | 26 | 8 | |||

| 12 | B6001ZZ | 28 | 8 | |||||||

| 15 | B6902ZZ | 28 | 7 | |||||||

| 20 | B6804ZZ | 32 | 7 | |||||||

| 50 | 0 -0.025 | 12 | 100 150 200 300 400 500 600 700 | B6301ZZ | 30 | 27 | 37 | 12 | ||

| 15 | B6202ZZ | 35 | 11 | |||||||

| 20 | B6904ZZ | 37 | 9 | |||||||

| 25 | B6905ZZ | 42 | 9 | |||||||

| 60 | 0 -0.030 | 15 | B6302ZZ | 35 | 32 | 42 | 13 | |||

| 20 | B6904ZZ | 37 | 9 | |||||||

| 25 | B6905ZZ | 42 | 9 | |||||||

| 30 | B6906ZZ | 47 | 9 | |||||||

| 80 | 0 -0.030 | 25 | B6305ZZ | 49 | 41 | 62 | 17 | |||

| 30 | B6206ZZ | 62 | 16 | |||||||

| 35 | B6007ZZ | 62 | 14 | |||||||

Alterations - Roller with Bearings