- Stan magazynowy

- Pokaż tylko pozycje magazynowe

- Length(mm)

- 41

- 48

- 59

- 66

- 78

- 96

- Main Body Material

- Stainless Steel

- EN 1.4301 Equiv.

- Main Body Surface Treatment

- Width (W)(mm)

- 36

- 48

- 62

- Number of Holes

- 2

- 3

- Type

- CAD

- 2D

- 3D

- Szacowane dni wysyłki

- Wszystko

- Możliwa wysyłka tego samego dnia

- W ciągu 5 dni robocze

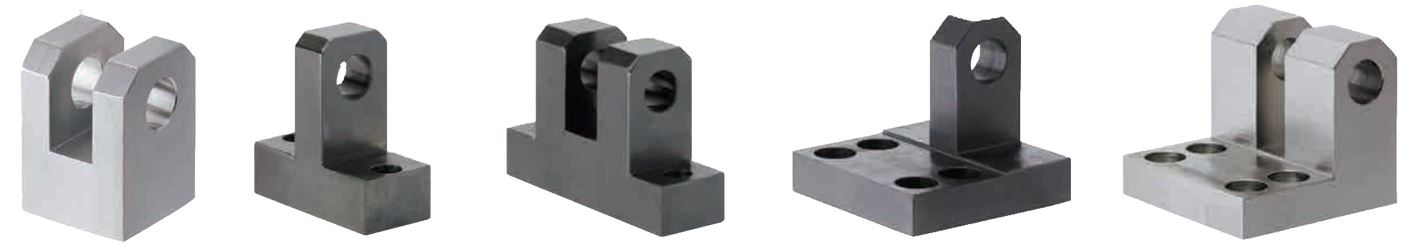

Flat hinges / rolled / stainless steel, steel / surface selectable / MISUMI

Numer części:

.Rysunek konturowy i tabela specyfikacji

Available dimensions and tolerances can be found under the tab More Information.

| Type | Material | Surface Treatment |

| SHHPS | EN 1.4401 Equiv. | - |

| SHHPSK | EN 1.4301 Equiv. | Brushed Finish |

| SHHPT | EN 1.0330 Equiv. or EN 1.0320 Equiv. (hot coiled) | Chrome Plating |

Further specifications can be found under the tab More Information.

| Part Number | - | Holes on One Side |

| SHHPS6 SHHPSD6 | - - | 2 3 |

Selection Details of Hinges

- Material: aluminum, plastic, stainless steel, steel, zinc alloy

- Coatings: polished, light-polished, stove-enamelled, brushed, anodized, sandblasted, mirror-polished, nickel-plated, chrome-plated

- Designs: flat hinge, wing hinge, spring hinge, damper hinge, torque hinge, hinge with stopper, hinge with latch function, piano band (rod hinge), hinge inside

- Bore hole: round hole, counterbore, conical counterbore, oblong hole

-Width: 8 mm to 120 mm

- Length: 20 mm to 1000 mm

Overview of the various designs as PDF

Description/Basics

Hinge

Hinges are among the fittings and are intended for movable storage. Similar to a joint, a hinge enables a bending, pivoting or folding movement. In principle, hinges are differentiated into a detachable hinge and an inseparable hinge. The separable hinge is also called a plug-in hinge. The advantage of a hinge is that the flap or door can be unhooked without great effort. Hinges are often used for maintenance doors, cabinet doors and windows. The hinge pin or hinge bolt serves as a connecting piece and axis of rotation at the same time. In most cases, the hinges are fastened using a screw connection, but hinges can also be welded to the hinge strap (flap/wing) in a permanent manner. When welding hinges, thinner sheet metals can deform due to the heat generation. Therefore, the screw version of the hinges is recommended for thinner wall thicknesses. You can buy many different hinges in the MISUMI online shop.

Flat hinge

Flat hinges are well suited in confined spaces or in places that may have to form a flat surface. These are often sheet metal hinges, which are made of rolled steel sheet metal. However, these flat hinges are also available as stainless steel hinges or plastic hinges. MISUMI also offers extruded flat hinges with a flat countersink as well as a cone countersink in its range. Flat hinges are also available without bore holes or unperforated to add custom bore holes or weld the hinge. The cranked hinges create a special shape. These hinges can compensate for a heel or height difference.

Materials

The MISUMI hinges are available in aluminum, plastic, stainless steel, steel and a zinc alloy. You can order these in the MISUMI Hinge Shop as flat sheet metal hinge and in stainless steel plate, up to extruded heavy-load hinges.

Coatings

The various treatments and surface treatments such as: polished, lightly polished, brushed, sand blasted, mirror polished, stove enamelled, anodized, nickel-plated, chrome-plated are available to you at MISUMI. With these coatings, the hinges are optimally protected against corrosion and always offer a suitable appearance with the versatile surface treatments.

Installation Information

To achieve smooth operation, it is essential to align the hinge. Therefore, an exact drilling pattern is necessary for the installation. For fine positioning, MISUMI offers elongated-hole hinges, which enable easy adjustment of the elements. After the correct position has been set, the screws can be tightened with a torque wrench. For longer hinges, the screws should be tightened from the inside to the outside so that the base of the hinge fits evenly.

Maintenance

Maintenance plays an important role in the ease of movement and long service life of a hinge. Prior to lubrication, a hinge should be cleaned of old lubricants and contaminants. After lubricating, the hinge should be moved several times so that the lubricant is evenly distributed in the eyelet and hinge bolts. Which lubricant is suitable depends on the respective application and environmental influences. For commercial applications, graphite oil is often used.

Hinge bases/hinge plates/hinge bolts

Lista numerów części

| Numer części |

|---|

Cena jednostkowa (bez VAT)(Cena jednostkowa z podatkiem) | Standardowa data wysyłki |

|---|

6.43 € ( 7.65 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

10.35 € ( 12.32 € ) | 5 dni robocze |

8.68 € ( 10.33 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

14.58 € ( 17.35 € ) | 5 dni robocze |

7.43 € ( 8.84 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

11.01 €4.07 € ( 4.84 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

9.45 € ( 11.25 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

14.81 € ( 17.62 € ) | 5 dni robocze |

12.35 € ( 14.70 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

16.33 € ( 19.43 € ) | 5 dni robocze |

13.85 € ( 16.48 € ) | 5 dni robocze |

19.82 € ( 23.59 € ) | 5 dni robocze |

Szczegółowe informacje

Kontury i specyfikacja

Overview of the various designs as PDF

| Part Number | Holes on One Side | * Allowable Load | Mass g | L | W | K | P | J | S | N | T | E | R | CR | D | SHHPS | SHHPSK | ||||

| Unit Price | Volume Discount Rate | Unit Price | Volume Discount Rate | ||||||||||||||||||

| Type | No. | kg | N | 1 ~ 8 pc (s). | 9~100 | 1 ~ 8 pc(s). | 9~100 | ||||||||||||||

| SHHPS SHHPSK | 5 | 2 | 9 | 88 | 43 | 41 | 36 | 8 | 25 | 7.5 | 21 | 5.5 | 2 | 4.6 | 4.6 | 7.5 | 5 | ||||

| 3 | 11 | 108 | 70 | 66 | |||||||||||||||||

| 6 | 2 | 12 | 117 | 60 | 48 | 48 | 9 | 30 | 8 | 32 | 6.5 | ||||||||||

| 3 | 15 | 147 | 98 | 78 | |||||||||||||||||

| 8 | 2 | 25 | 245 | 130 | 59 | 62 | 11 | 37 | 10 | 42 | 3 | 5.6 | 5.6 | 10 | |||||||

| 3 | 38 | 372 | 230 | 96 | 6.1 | 6.1 | 6 | ||||||||||||||

| 845 | 2 | 30 | 294 | 190 | 70 | 80 | 13.5 | 43 | 16.5 | 47 | 5.6 | 5.6 | 5 | - | - | ||||||

| 3 | 40 | 392 | 325 | 113 | 6.1 | 6.1 | 6 | - | - | ||||||||||||

| Part Number | Holes on One Side | * Allowable Load | Mass g | L | W | K | P | J | S | N | T | E | R | CR | D | Unit Price | Volume Discount Rate | ||

| Type | No. | kg | N | 1 ~ 8 pc (s). | 9~100 | ||||||||||||||

| SHHPT | 5 | 2 | 9 | 88 | 36 | 41 | 36 | 8 | 25 | 7.5 | 21 | 5.5 | 2 | 4.6 | 4.6 | 4 | 5 | ||

| 3 | 11 | 108 | 59 | 66 | |||||||||||||||

| 6 | 2 | 12 | 117 | 50 | 48 | 48 | 9 | 30 | 8 | 32 | 6.5 | ||||||||

| 3 | 15 | 147 | 83 | 78 | |||||||||||||||

| 8 | 2 | 25 | 245 | 124 | 59 | 62 | 11 | 37 | 10 | 42 | 3.2 | 6.5 | 6.5 | 5 | 6 | ||||

| 3 | 38 | 372 | 207 | 96 | |||||||||||||||

| 845 | 2 | 30 | 294 | 181 | 70 | 80 | 13.5 | 43 | 16.5 | 47 | |||||||||

| 3 | 40 | 392 | 298 | 113 | |||||||||||||||