Toothed belt / #GT / CR / glass fibre

- Promotional pricing ends 30/11/2024

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Back to the Category Timing Belt

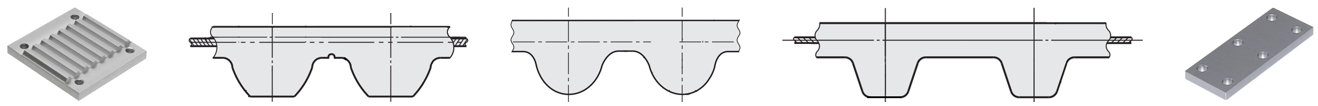

Technical Drawing - Timing Belts

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Timing Belts

| Type | Material | |

| GBN | Back Rubber | Chloroprene Rubber |

| Tooth Rubber | ||

| Core Wire | Glass Fiber Cord | |

| Tooth Fabric | Nylon Cloth | |

Further specifications can be found under the tab More information.

Composition of a Product Code - Timing Belts

| Part Number | ||||||

| Type | Belt Number | Belt Nominal Width | ||||

| GBN | 200 2GT | - | 60 | |||

General Information - Timing Belts

Timing Belt Selection Details

- Material: chloroprene rubber (neoprene), polyurethane (PU)

- Tension cord: glass fibre, aramid fibre, steel

- Width (mm): 1 to 101.6

- Width (in.): 0.19 to 4

- Profile (metric): T5, T10, AT5, AT10, S2M, S3M, S5M, S8M, S14M, MTS8M, EV5GT, EV8YU, 2GT, 3GT, MA3, MA5, MA8, P2M, P3M, P5M, P8M, UP5M, UP8M

- Profile (in.): MXL, XL, L, H

Description/Basics

Timing belts for mechanical engineering are intended for force and power transmission. Depending on the interlocking of the profile, they can alternatively be used for the material flow (transportation) or for positioning.

Timing belts are more maintenance-friendly, efficient and durable compared to roller chains.

Maintenance-friendly: timing belts do not require lubrication, are easy to replace and are very durable, as they do not sag. These properties significantly reduce maintenance costs.

Efficient: drive belts are largely made of natural rubber or polyurethane. As a result, timing belts withstand high speeds. A further advantage of these materials is the weight reduction compared to conventional metal drives. Timing belts are also known for low-noise running and contribute to the general smooth running of an application.

Durability: due to the inserted tension cord made of glass fibre or aramid fibre (Kevlar), timing belts can withstand high tensile stresses and do not tend to sag. An additional layer of nylon fabric on the interlocked side reduces wear due to abrasion and increases the service life.

Timing belts can be used in many ways. The belt profile that suits your application depends on the task of the timing belt. MISUMI offers a suitable belt profile for almost every type of application.

Drive: timing belts are used even at high torque. Drive belts with a rounded trapezoidal profile (e.g., S8M) are often used to drive mechanical components. These are particularly well suited for slip-free transmission of high forces, which can occur in drives of various applications or machines.

Positioning: a semi-circular profile (e.g., GT) is often used for positioning via timing belts. Round profile timing belts are often used in 3D printers and precise scanners. The round shape also offers the advantage that there is little play (reverse play) when the direction changes.

Material flow: timing belts can also be used to transport loads in conveyor systems. A straight trapezoidal profile is often used for this purpose (e.g., AT ). This profile provides a large profile area for load intake and transmission. The MISUMI range also includes conveyor timing belts with nylon fabric on the bearing surface.

An overview of the profile forms by application type can be found in the PDF Overview.

The amount of transmission power depends on many factors. The exact maximum load must be considered and calculated individually according to the application. The calculation for timing belts can be found in the selection of Timing Belts as PDF.

In order not to fall below the minimum number of teeth, the minimum size of the timing pulleys should be considered individually.

In general, a timing belt should be provided with the appropriate pretension to maximize the service life of the timing belt. If the pretension is too low, a jump (slip) can cause wear of the timing belt.

Application Examples - Timing Belts

Application example: workpiece carrier

(1) Stopper bolt with rubber, (2) belt conveyor, (3) workpiece carrier

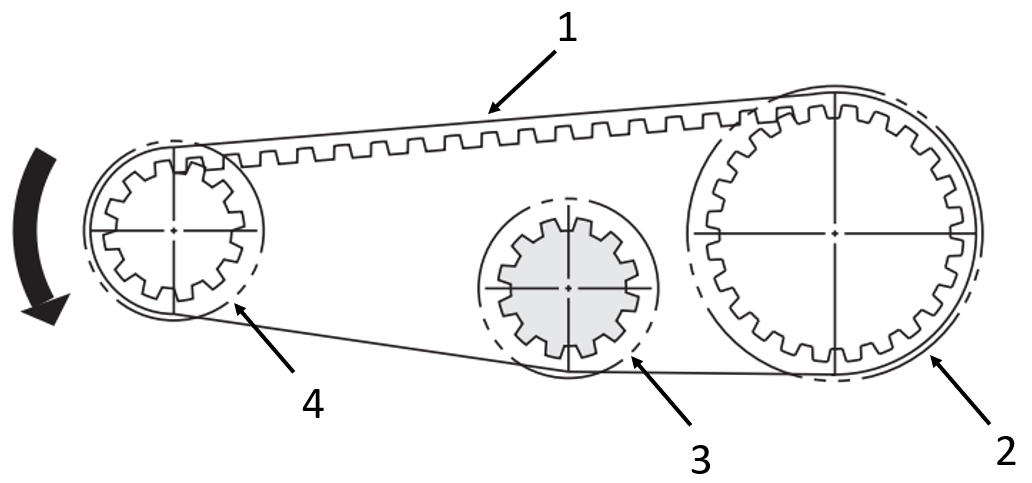

Application example: of toothed belt drives

(1) Toothed belt, (2) driven Timing pulleys with crimp disc, (3) idler pulley with crimp disc, (4) driving Timing pulleys with crimp disc

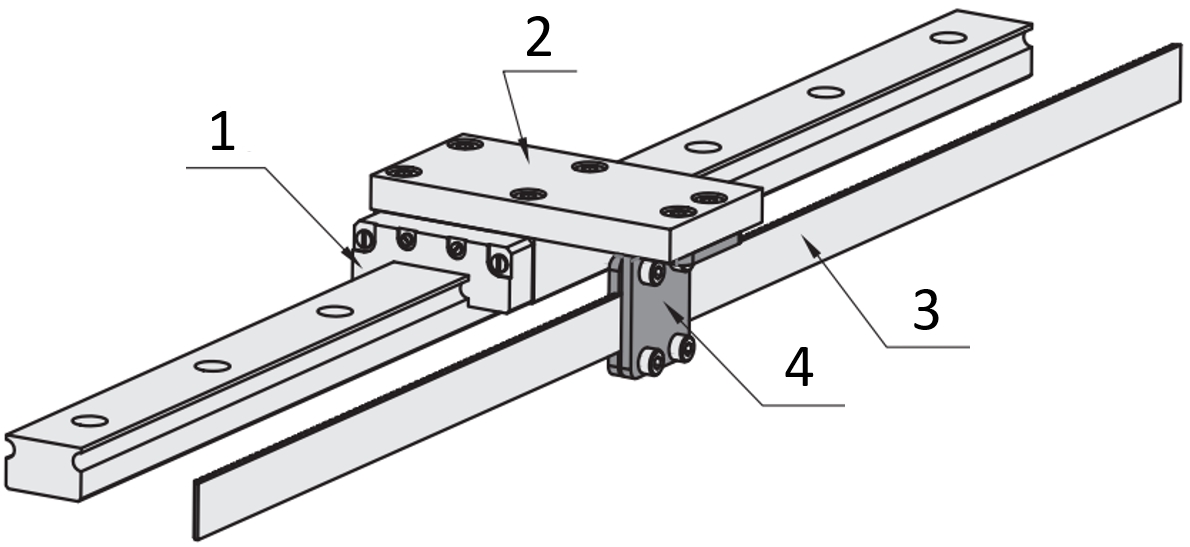

Application example: Timing belt

(1) Linear guide, (2) mounting plate, (3) Timing belt, (4) Screw-on terminal

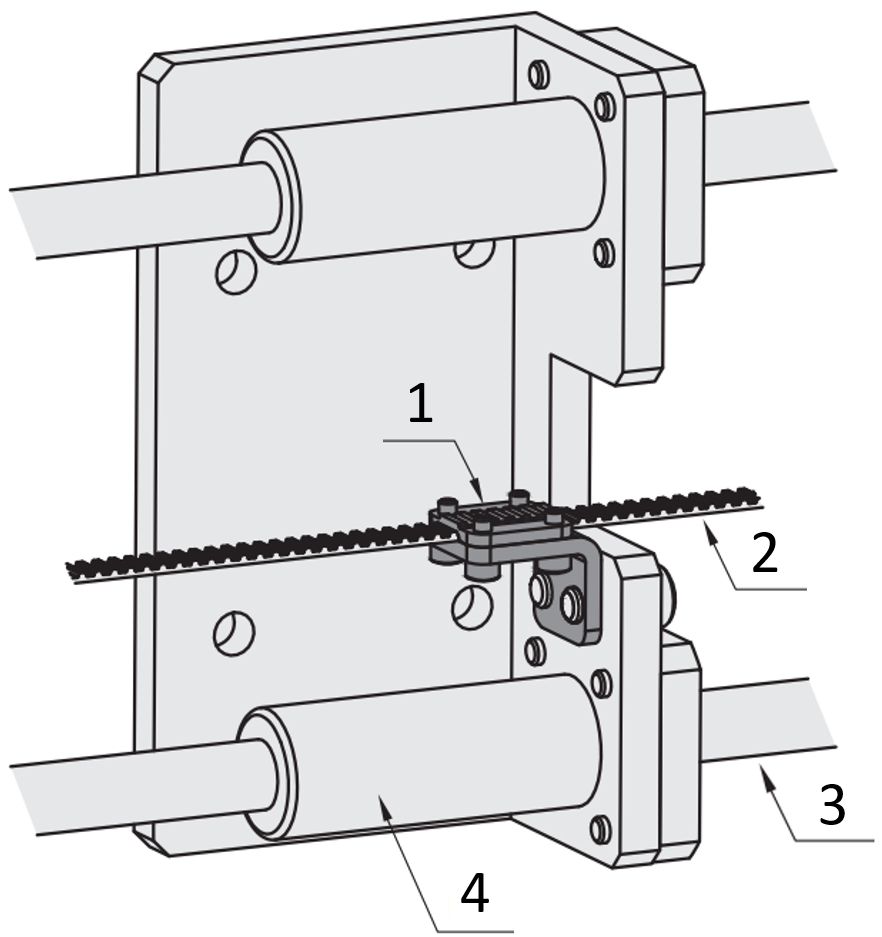

Application example: Timing belt

(1) Bolt-on terminal, (2) Timing belt, (3) Linear shaft, (4) Linear bushings

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Belt Type | Belt Width (mm) (mm) | Circumference Length (mm) | Number of Teeth (Teeth) | |

|---|---|---|---|---|---|---|---|---|---|

3.17 € | 1 | 7 Days | 10 | 2GT | 4 | 100 | 50 | ||

4.43 € | 1 | 7 Days | 10 | 2GT | 6 | 100 | 50 | ||

5.57 € | 1 | 7 Days | 10 | 2GT | 9 | 100 | 50 | ||

9.23 € | 1 | 7 Days | 10 | 3GT | 6 | 1005 | 335 | ||

13.16 € | 1 | 7 Days | 10 | 3GT | 9 | 1005 | 335 | ||

20.88 € | 1 | 7 Days | 10 | 3GT | 15 | 1005 | 335 | ||

9.23 € | 1 | 7 Days | 10 | 3GT | 6 | 1008 | 336 | ||

13.16 € | 1 | 7 Days | 10 | 3GT | 9 | 1008 | 336 | ||

20.88 € | 1 | 7 Days | 10 | 3GT | 15 | 1008 | 336 | ||

9.23 € | 1 | 7 Days | 10 | 3GT | 6 | 1014 | 338 | ||

13.16 € | 1 | 7 Days | 10 | 3GT | 9 | 1014 | 338 | ||

20.88 € | 1 | 7 Days | 10 | 3GT | 15 | 1014 | 338 | ||

3.17 € | 1 |

Same day

Stock | 10 | 2GT | 4 | 102 | 51 | ||

4.43 € | 1 | 7 Days | 10 | 2GT | 6 | 102 | 51 | ||

5.57 € | 1 | 7 Days | 10 | 2GT | 9 | 102 | 51 | ||

4.56 € | 1 | 7 Days | 10 | 3GT | 6 | 102 | 34 | ||

6.45 € | 1 | 7 Days | 10 | 3GT | 9 | 102 | 34 | ||

10.12 € | 1 | 7 Days | 10 | 3GT | 15 | 102 | 34 | ||

4.56 € | 1 | 7 Days | 10 | 3GT | 6 | 105 | 35 | ||

9.36 € | 1 | 7 Days | 10 | 3GT | 6 | 1050 | 350 | ||

6.45 € | 1 | 7 Days | 10 | 3GT | 9 | 105 | 35 | ||

13.53 € | 1 | 7 Days | 10 | 3GT | 9 | 1050 | 350 | ||

10.12 € | 1 | 7 Days | 10 | 3GT | 15 | 105 | 35 | ||

21.64 € | 1 | 7 Days | 10 | 3GT | 15 | 1050 | 350 | ||

9.36 € | 1 | 7 Days | 10 | 3GT | 6 | 1059 | 353 | ||

13.53 € | 1 | 7 Days | 10 | 3GT | 9 | 1059 | 353 | ||

21.64 € | 1 | 7 Days | 10 | 3GT | 15 | 1059 | 353 | ||

3.17 € | 1 |

Same day

Stock | 10 | 2GT | 4 | 106 | 53 | ||

4.43 € | 1 | 7 Days | 10 | 2GT | 6 | 106 | 53 | ||

5.57 € | 1 | 7 Days | 10 | 2GT | 9 | 106 | 53 | ||

9.36 € | 1 | 7 Days | 10 | 3GT | 6 | 1068 | 356 | ||

13.53 € | 1 | 7 Days | 10 | 3GT | 9 | 1068 | 356 | ||

21.64 € | 1 | 7 Days | 10 | 3GT | 15 | 1068 | 356 | ||

9.36 € | 1 | 7 Days | 10 | 3GT | 6 | 1071 | 357 | ||

13.53 € | 1 | 7 Days | 10 | 3GT | 9 | 1071 | 357 | ||

21.64 € | 1 | 7 Days | 10 | 3GT | 15 | 1071 | 357 | ||

3.17 € | 1 | 7 Days | 10 | 2GT | 4 | 108 | 54 | ||

4.43 € | 1 | 7 Days | 10 | 2GT | 6 | 108 | 54 | ||

5.57 € | 1 | 7 Days | 10 | 2GT | 9 | 108 | 54 | ||

4.69 € | 1 | 7 Days | 10 | 3GT | 6 | 108 | 36 | ||

6.70 € | 1 | 7 Days | 10 | 3GT | 9 | 108 | 36 | ||

10.63 € | 1 | 7 Days | 10 | 3GT | 15 | 108 | 36 | ||

9.74 € | 1 | 7 Days | 10 | 3GT | 6 | 1086 | 362 | ||

13.92 € | 1 | 7 Days | 10 | 3GT | 9 | 1086 | 362 | ||

22.27 € | 1 | 7 Days | 10 | 3GT | 15 | 1086 | 362 | ||

9.74 € | 1 | 7 Days | 10 | 3GT | 6 | 1098 | 366 | ||

13.92 € | 1 | 7 Days | 10 | 3GT | 9 | 1098 | 366 | ||

22.27 € | 1 | 7 Days | 10 | 3GT | 15 | 1098 | 366 | ||

3.17 € | 1 | 7 Days | 10 | 2GT | 4 | 110 | 55 | ||

4.43 € | 1 | 7 Days | 10 | 2GT | 6 | 110 | 55 | ||

5.57 € | 1 | 7 Days | 10 | 2GT | 9 | 110 | 55 | ||

4.69 € | 1 | 7 Days | 10 | 3GT | 6 | 111 | 37 | ||

6.70 € | 1 | 7 Days | 10 | 3GT | 9 | 111 | 37 | ||

10.63 € | 1 | 7 Days | 10 | 3GT | 15 | 111 | 37 | ||

9.74 € | 1 | 7 Days | 10 | 3GT | 6 | 1113 | 371 | ||

13.92 € | 1 | 7 Days | 10 | 3GT | 9 | 1113 | 371 | ||

22.27 € | 1 | 7 Days | 10 | 3GT | 15 | 111 | 371 | ||

3.17 € | 1 | 7 Days | 10 | 2GT | 4 | 112 | 56 | ||

4.43 € | 1 | 7 Days | 10 | 2GT | 6 | 112 | 56 | ||

5.57 € | 1 | 7 Days | 10 | 2GT | 9 | 112 | 56 |

Loading...

Back to the Category Timing Belt

Technical Drawing - Timing Belts

Open the technical drawing in the new window

Specification Tables - Timing Belts

| Type | Pitch | R1 | R2 | R3 | b | H | h | i | PLD | Unit Mass g/m (Width: 10mm) |

| 2GT | 2 | 0.15 | 1.00 | 0.555 | 0.40 | 1.38 | 0.75 | 0.63 | 0.254 | 13.0 |

| 3GT | 3 | 0.25 | 1.52 | 0.85 | 0.61 | 2.40 | 1.14 | 1.26 | 0.381 | 25.0 |

Belt Circumference Length is the length of Core Wire.

Features and Cautions >> P.1375

Selection Method >> P.2253

| Part Number | Number of Teeth | Belt Circumference Length (mm) | Unit Price | ||||

| Type | Belt Number | Belt Nominal Width | Belt Nominal Width | ||||

| 40 | 60 | 90 | |||||

| GBN (Rubber) | 66 2GT | 40 (4mm) 60 (6mm) 90 (9mm) | 33 | 66 | |||

| 72 2GT | 36 | 72 | |||||

| 74 2GT | 37 | 74 | |||||

| 76 2GT | 38 | 76 | |||||

| 78 2GT | 39 | 78 | |||||

| 80 2GT | 40 | 80 | |||||

| 82 2GT | 41 | 82 | |||||

| 84 2GT | 42 | 84 | |||||

| 86 2GT | 43 | 86 | |||||

| 88 2GT | 44 | 88 | |||||

| 90 2GT | 45 | 90 | |||||

| 92 2GT | 46 | 92 | |||||

| 94 2GT | 47 | 94 | |||||

| 96 2GT | 48 | 96 | |||||

| 98 2GT | 49 | 98 | |||||

| 100 2GT | 50 | 100 | |||||

| 102 2GT | 51 | 102 | |||||

| 106 2GT | 53 | 106 | |||||

| 108 2GT | 54 | 108 | |||||

| 110 2GT | 55 | 110 | |||||

| 112 2GT | 56 | 112 | |||||

| 114 2GT | 57 | 114 | |||||

| 116 2GT | 58 | 116 | |||||

| 118 2GT | 59 | 118 | |||||

| 120 2GT | 60 | 120 | |||||

| 122 2GT | 61 | 122 | |||||

| 124 2GT | 62 | 124 | |||||

| 126 2GT | 63 | 126 | |||||

| 128 2GT | 64 | 128 | |||||

| 130 2GT | 65 | 130 | |||||

| 132 2GT | 66 | 132 | |||||

| 134 2GT | 67 | 134 | |||||

| 136 2GT | 68 | 136 | |||||

| 138 2GT | 69 | 138 | |||||

| 140 2GT | 70 | 140 | |||||

| 142 2GT | 71 | 142 | |||||

| 144 2GT | 72 | 144 | |||||

| 146 2GT | 73 | 146 | |||||

| 148 2GT | 74 | 148 | |||||

| 150 2GT | 75 | 150 | |||||

| 152 2GT | 76 | 152 | |||||

| 154 2GT | 77 | 154 | |||||

| 156 2GT | 78 | 156 | |||||

| 158 2GT | 79 | 158 | |||||

| 160 2GT | 80 | 160 | |||||

| 162 2GT | 81 | 162 | |||||

| 164 2GT | 82 | 164 | |||||

| 166 2GT | 83 | 166 | |||||

| 168 2GT | 84 | 168 | |||||

| 170 2GT | 85 | 170 | |||||

| 172 2GT | 86 | 172 | |||||

| 174 2GT | 87 | 174 | |||||

| 176 2GT | 88 | 176 | |||||

| 178 2GT | 89 | 178 | |||||

| 180 2GT | 90 | 180 | |||||

| 182 2GT | 91 | 182 | |||||

| 184 2GT | 92 | 184 | |||||

| 186 2GT | 93 | 186 | |||||

| 188 2GT | 94 | 188 | |||||

| 190 2GT | 95 | 190 | |||||

| 192 2GT | 96 | 192 | |||||

| 194 2GT | 97 | 194 | |||||

| 196 2GT | 98 | 196 | |||||

| 200 2GT | 100 | 200 | |||||

| 202 2GT | 101 | 202 | |||||

| 204 2GT | 102 | 204 | |||||

| 208 2GT | 104 | 208 | |||||

| 210 2GT | 105 | 210 | |||||

| 212 2GT | 106 | 212 | |||||

| 214 2GT | 107 | 214 | |||||

| 216 2GT | 108 | 216 | |||||

| 220 2GT | 110 | 220 | |||||

| 224 2GT | 112 | 224 | |||||

| 226 2GT | 113 | 226 | |||||

| 228 2GT | 114 | 228 | |||||

| 230 2GT | 115 | 230 | |||||

| 232 2GT | 116 | 232 | |||||

| 236 2GT | 118 | 236 | |||||

| 240 2GT | 120 | 240 | |||||

| 242 2GT | 121 | 242 | |||||

| 244 2GT | 122 | 244 | |||||

| 248 2GT | 124 | 248 | |||||

| 250 2GT | 125 | 250 | |||||

| 252 2GT | 126 | 252 | |||||

| 254 2GT | 127 | 254 | |||||

| 256 2GT | 128 | 256 | |||||

| 258 2GT | 129 | 258 | |||||

| 260 2GT | 130 | 260 | |||||

| 264 2GT | 132 | 264 | |||||

| 266 2GT | 133 | 266 | |||||

| 268 2GT | 134 | 268 | |||||

| 270 2GT | 135 | 270 | |||||

| 278 2GT | 139 | 278 | |||||

| 280 2GT | 140 | 280 | |||||

| 282 2GT | 141 | 282 | |||||

| 284 2GT | 142 | 284 | |||||

| 286 2GT | 143 | 286 | |||||

| 288 2GT | 144 | 288 | |||||

| 290 2GT | 145 | 290 | |||||

| Part Number | Number of Teeth | Belt Circumference Length (mm) | Unit Price | ||||

| Type | Belt Number | Belt Nominal Width | Belt Nominal Width | ||||

| 40 | 60 | 90 | |||||

| GBN (Rubber) | 292 2GT | 40 (4mm) 60 (6mm) 90 (9mm) | 146 | 292 | |||

| 294 2GT | 147 | 294 | |||||

| 300 2GT | 150 | 300 | |||||

| 302 2GT | 151 | 302 | |||||

| 304 2GT | 152 | 304 | |||||

| 308 2GT | 154 | 308 | |||||

| 310 2GT | 155 | 310 | |||||

| 314 2GT | 157 | 314 | |||||

| 318 2GT | 159 | 318 | |||||

| 320 2GT | 160 | 320 | |||||

| 322 2GT | 161 | 322 | |||||

| 324 2GT | 162 | 324 | |||||

| 326 2GT | 163 | 326 | |||||

| 328 2GT | 164 | 328 | |||||

| 332 2GT | 166 | 332 | |||||

| 336 2GT | 168 | 336 | |||||

| 338 2GT | 169 | 338 | |||||

| 340 2GT | 170 | 340 | |||||

| 344 2GT | 172 | 344 | |||||

| 346 2GT | 173 | 346 | |||||

| 348 2GT | 174 | 348 | |||||

| 350 2GT | 175 | 350 | |||||

| 352 2GT | 176 | 352 | |||||

| 354 2GT | 177 | 354 | |||||

| 358 2GT | 179 | 358 | |||||

| 360 2GT | 180 | 360 | |||||

| 366 2GT | 183 | 366 | |||||

| 370 2GT | 185 | 370 | |||||

| 372 2GT | 186 | 372 | |||||

| 376 2GT | 188 | 376 | |||||

| 380 2GT | 190 | 380 | |||||

| 382 2GT | 191 | 382 | |||||

| 386 2GT | 193 | 386 | |||||

| 394 2GT | 197 | 394 | |||||

| 400 2GT | 200 | 400 | |||||

| 406 2GT | 203 | 406 | |||||

| 412 2GT | 206 | 412 | |||||

| 420 2GT | 210 | 420 | |||||

| 426 2GT | 213 | 426 | |||||

| 430 2GT | 215 | 430 | |||||

| 436 2GT | 218 | 436 | |||||

| 440 2GT | 220 | 440 | |||||

| 444 2GT | 222 | 444 | |||||

| 446 2GT | 223 | 446 | |||||

| 448 2GT | 224 | 448 | |||||

| 452 2GT | 226 | 452 | |||||

| 460 2GT | 230 | 460 | |||||

| 470 2GT | 235 | 470 | |||||

| 478 2GT | 239 | 478 | |||||

| 484 2GT | 242 | 484 | |||||

| 486 2GT | 243 | 486 | |||||

| 488 2GT | 244 | 488 | |||||

| 492 2GT | 246 | 492 | |||||

| 494 2GT | 247 | 494 | |||||

| 500 2GT | 250 | 500 | |||||

| 502 2GT | 251 | 502 | |||||

| 504 2GT | 252 | 504 | |||||

| 506 2GT | 253 | 506 | |||||

| 516 2GT | 258 | 516 | |||||

| 524 2GT | 262 | 524 | |||||

| 530 2GT | 265 | 530 | |||||

| 544 2GT | 272 | 544 | |||||

| 550 2GT | 275 | 550 | |||||

| 558 2GT | 279 | 558 | |||||

| 570 2GT | 285 | 570 | |||||

| 572 2GT | 286 | 572 | |||||

| 578 2GT | 289 | 578 | |||||

| 586 2GT | 293 | 586 | |||||

| 598 2GT | 299 | 598 | |||||

| 600 2GT | 300 | 600 | |||||

| 606 2GT | 303 | 606 | |||||

| 616 2GT | 308 | 616 | |||||

| 630 2GT | 315 | 630 | |||||

| 634 2GT | 317 | 634 | |||||

| 646 2GT | 323 | 646 | |||||

| 660 2GT | 330 | 660 | |||||

| 670 2GT | 335 | 670 | |||||

| 676 2GT | 338 | 676 | |||||

| 690 2GT | 345 | 690 | |||||

| 696 2GT | 348 | 696 | |||||

| 702 2GT | 351 | 702 | |||||

| 726 2GT | 363 | 726 | |||||

| 742 2GT | 371 | 742 | |||||

| 752 2GT | 376 | 752 | |||||

| 760 2GT | 380 | 760 | |||||

| 772 2GT | 386 | 772 | |||||

| 782 2GT | 391 | 782 | |||||

| 800 2GT | 400 | 800 | |||||

| 810 2GT | 405 | 810 | |||||

| 852 2GT | 426 | 852 | |||||

| 860 2GT | 430 | 860 | |||||

| 866 2GT | 433 | 866 | |||||

| 892 2GT | 446 | 892 | |||||

| 900 2GT | 450 | 900 | |||||

| 930 2GT | 465 | 930 | |||||

| 950 2GT | 475 | 950 | |||||

| 976 2GT | 488 | 976 | |||||

| 994 2GT | 497 | 994 | |||||

| Part Number | Number of Teeth | Belt Circumference Length (mm) | Unit Price | ||||

| Type | Belt Number | Belt Nominal Width | Belt Nominal Width | ||||

| 60 | 90 | 150 | |||||

| GBN (Rubber) | 102 3GT | 60 (6mm) 90 (9mm) 150 (15mm) | 34 | 102 | |||

| 105 3GT | 35 | 105 | |||||

| 108 3GT | 36 | 108 | |||||

| 111 3GT | 37 | 111 | |||||

| 114 3GT | 38 | 114 | |||||

| 117 3GT | 39 | 117 | |||||

| 120 3GT | 40 | 120 | |||||

| 123 3GT | 41 | 123 | |||||

| 126 3GT | 42 | 126 | |||||

| 129 3GT | 43 | 129 | |||||

| 132 3GT | 44 | 132 | |||||

| 135 3GT | 45 | 135 | |||||

| 138 3GT | 46 | 138 | |||||

| 141 3GT | 47 | 141 | |||||

| 144 3GT | 48 | 144 | |||||

| 147 3GT | 49 | 147 | |||||

| 150 3GT | 50 | 150 | |||||

| 156 3GT | 52 | 156 | |||||

| 159 3GT | 53 | 159 | |||||

| 162 3GT | 54 | 162 | |||||

| 168 3GT | 56 | 168 | |||||

| 174 3GT | 58 | 174 | |||||

| 177 3GT | 59 | 177 | |||||

| 180 3GT | 60 | 180 | |||||

| 186 3GT | 62 | 186 | |||||

| 189 3GT | 63 | 189 | |||||

| 192 3GT | 64 | 192 | |||||

| 195 3GT | 65 | 195 | |||||

| 198 3GT | 66 | 198 | |||||

| 201 3GT | 67 | 201 | |||||

| 204 3GT | 68 | 204 | |||||

| 207 3GT | 69 | 207 | |||||

| 210 3GT | 70 | 210 | |||||

| 213 3GT | 71 | 213 | |||||

| 216 3GT | 72 | 216 | |||||

| 222 3GT | 74 | 222 | |||||

| 225 3GT | 75 | 225 | |||||

| 228 3GT | 76 | 228 | |||||

| 231 3GT | 77 | 231 | |||||

| 234 3GT | 78 | 234 | |||||

| 237 3GT | 79 | 237 | |||||

| 240 3GT | 80 | 240 | |||||

| 243 3GT | 81 | 243 | |||||

| 246 3GT | 82 | 246 | |||||

| 249 3GT | 83 | 249 | |||||

| 252 3GT | 84 | 252 | |||||

| 255 3GT | 85 | 255 | |||||

| 258 3GT | 86 | 258 | |||||

| 264 3GT | 88 | 264 | |||||

| 267 3GT | 89 | 267 | |||||

| 270 3GT | 90 | 270 | |||||

| 273 3GT | 91 | 273 | |||||

| 276 3GT | 92 | 276 | |||||

| 282 3GT | 94 | 282 | |||||

| 285 3GT | 95 | 285 | |||||

| 288 3GT | 96 | 288 | |||||

| 291 3GT | 97 | 291 | |||||

| 297 3GT | 99 | 297 | |||||

| 300 3GT | 100 | 300 | |||||

| 303 3GT | 101 | 303 | |||||

| 309 3GT | 103 | 309 | |||||

| 312 3GT | 104 | 312 | |||||

| 315 3GT | 105 | 315 | |||||

| 318 3GT | 106 | 318 | |||||

| 324 3GT | 108 | 324 | |||||

| 327 3GT | 109 | 327 | |||||

| 330 3GT | 110 | 330 | |||||

| 333 3GT | 111 | 333 | |||||

| 336 3GT | 112 | 336 | |||||

| 339 3GT | 113 | 339 | |||||

| 342 3GT | 114 | 342 | |||||

| 345 3GT | 115 | 345 | |||||

| 348 3GT | 116 | 348 | |||||

| 351 3GT | 117 | 351 | |||||

| 354 3GT | 118 | 354 | |||||

| 357 3GT | 119 | 357 | |||||

| 363 3GT | 121 | 363 | |||||

| 366 3GT | 122 | 366 | |||||

| 369 3GT | 123 | 369 | |||||

| 375 3GT | 125 | 375 | |||||

| 378 3GT | 126 | 378 | |||||

| 381 3GT | 127 | 381 | |||||

| 384 3GT | 128 | 384 | |||||

| 387 3GT | 129 | 387 | |||||

| 393 3GT | 131 | 393 | |||||

| 396 3GT | 132 | 396 | |||||

| 399 3GT | 133 | 399 | |||||

| 402 3GT | 134 | 402 | |||||

| 405 3GT | 135 | 405 | |||||

| 408 3GT | 136 | 408 | |||||

| 414 3GT | 138 | 414 | |||||

| 417 3GT | 139 | 417 | |||||

| 420 3GT | 140 | 420 | |||||

| 423 3GT | 141 | 423 | |||||

| 426 3GT | 142 | 426 | |||||

| 432 3GT | 144 | 432 | |||||

| 444 3GT | 148 | 444 | |||||

| 447 3GT | 149 | 447 | |||||

| 453 3GT | 151 | 453 | |||||

| 456 3GT | 152 | 456 | |||||

| 459 3GT | 153 | 459 | |||||

| 462 3GT | 154 | 462 | |||||

| 471 3GT | 157 | 471 | |||||

| 480 3GT | 160 | 480 | |||||

| Part Number | Number of Teeth | Belt Circumference Length (mm) | Unit Price | ||||

| Type | Belt Number | Belt Nominal Width | Belt Nominal Width | ||||

| 60 | 90 | 150 | |||||

| GBN (Rubber) | 486 3GT | 60 (6mm) 90 (9mm) 150 (15mm) | 162 | 486 | |||

| 489 3GT | 163 | 489 | |||||

| 495 3GT | 165 | 495 | |||||

| 501 3GT | 167 | 501 | |||||

| 504 3GT | 168 | 504 | |||||

| 510 3GT | 170 | 510 | |||||

| 513 3GT | 171 | 513 | |||||

| 522 3GT | 174 | 522 | |||||

| 525 3GT | 175 | 525 | |||||

| 531 3GT | 177 | 531 | |||||

| 537 3GT | 179 | 537 | |||||

| 540 3GT | 180 | 540 | |||||

| 543 3GT | 181 | 543 | |||||

| 549 3GT | 183 | 549 | |||||

| 552 3GT | 184 | 552 | |||||

| 558 3GT | 186 | 558 | |||||

| 561 3GT | 187 | 561 | |||||

| 564 3GT | 188 | 564 | |||||

| 570 3GT | 190 | 570 | |||||

| 576 3GT | 192 | 576 | |||||

| 579 3GT | 193 | 579 | |||||

| 582 3GT | 194 | 582 | |||||

| 588 3GT | 196 | 588 | |||||

| 591 3GT | 197 | 591 | |||||

| 597 3GT | 199 | 597 | |||||

| 600 3GT | 200 | 600 | |||||

| 603 3GT | 201 | 603 | |||||

| 609 3GT | 203 | 609 | |||||

| 612 3GT | 204 | 612 | |||||

| 618 3GT | 206 | 618 | |||||

| 624 3GT | 208 | 624 | |||||

| 633 3GT | 211 | 633 | |||||

| 639 3GT | 213 | 639 | |||||

| 642 3GT | 214 | 642 | |||||

| 651 3GT | 217 | 651 | |||||

| 654 3GT | 218 | 654 | |||||

| 666 3GT | 222 | 666 | |||||

| 672 3GT | 224 | 672 | |||||

| 675 3GT | 225 | 675 | |||||

| 681 3GT | 227 | 681 | |||||

| 687 3GT | 229 | 687 | |||||

| 690 3GT | 230 | 690 | |||||

| 693 3GT | 231 | 693 | |||||

| 699 3GT | 233 | 699 | |||||

| 702 3GT | 234 | 702 | |||||

| 705 3GT | 235 | 705 | |||||

| 708 3GT | 236 | 708 | |||||

| 720 3GT | 240 | 720 | |||||

| 729 3GT | 243 | 729 | |||||

| 741 3GT | 247 | 741 | |||||

| 744 3GT | 248 | 744 | |||||

| 750 3GT | 250 | 750 | |||||

| 756 3GT | 252 | 756 | |||||

| 765 3GT | 255 | 765 | |||||

| 774 3GT | 258 | 774 | |||||

| 783 3GT | 261 | 783 | |||||

| 789 3GT | 263 | 789 | |||||

| 810 3GT | 270 | 810 | |||||

| 822 3GT | 274 | 822 | |||||

| 840 3GT | 280 | 840 | |||||

| 852 3GT | 284 | 852 | |||||

| 858 3GT | 286 | 858 | |||||

| 870 3GT | 290 | 870 | |||||

| 882 3GT | 294 | 882 | |||||

| 900 3GT | 300 | 900 | |||||

| 912 3GT | 304 | 912 | |||||

| 924 3GT | 308 | 924 | |||||

| 927 3GT | 309 | 927 | |||||

| 936 3GT | 312 | 936 | |||||

| 948 3GT | 316 | 948 | |||||

| 960 3GT | 320 | 960 | |||||

| 963 3GT | 321 | 963 | |||||

| 966 3GT | 322 | 966 | |||||

| 972 3GT | 324 | 972 | |||||

| 981 3GT | 327 | 981 | |||||

| 993 3GT | 331 | 993 | |||||

| 996 3GT | 332 | 996 | |||||

| 1005 3GT | 335 | 1005 | |||||

| 1008 3GT | 336 | 1008 | |||||

| 1014 3GT | 338 | 1014 | |||||

| 1050 3GT | 350 | 1050 | |||||

| 1059 3GT | 353 | 1059 | |||||

| 1068 3GT | 356 | 1068 | |||||

| 1071 3GT | 357 | 1071 | |||||

| 1086 3GT | 362 | 1086 | |||||

| 1098 3GT | 366 | 1098 | |||||

| 1113 3GT | 371 | 1113 | |||||

| 1137 3GT | 379 | 1137 | |||||

| 1170 3GT | 390 | 1170 | |||||

| 1188 3GT | 396 | 1188 | |||||

| 1212 3GT | 404 | 1212 | |||||

| 1215 3GT | 405 | 1215 | |||||

| 1260 3GT | 420 | 1260 | |||||

| 1290 3GT | 430 | 1290 | |||||

| 1299 3GT | 433 | 1299 | |||||

| 1305 3GT | 435 | 1305 | |||||

| 1326 3GT | 442 | 1326 | |||||

| 1335 3GT | 445 | 1335 | |||||

| 1374 3GT | 458 | 1374 | |||||

| 1386 3GT | 462 | 1386 | |||||

| 1422 3GT | 474 | 1422 | |||||

| 1446 3GT | 482 | 1446 | |||||

| 1521 3GT | 507 | 1521 | |||||

Basic information

| Belt shape | Closed End | Belt tooth surface | Standard (Single Sided) | Belt material | Rubber Belt |

|---|---|---|---|---|---|

| Core Wire Material | Glass Fiber | Belt-shaped type | Circular Tooth Profile GT Belt | Transmission torque | High Torque Transmission |

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Belt Type

- 2GT

- 3GT

-

Belt Width (mm)(mm)

-

Circumference Length(mm)

- 66

- 72

- 74

- 76

- 78

- 80

- 82

- 84

- 86

- 88

- 90

- 92

- 94

- 96

- 98

- 100

- 102

- 105

- 106

- 108

- 110

- 111

- 112

- 114

- 116

- 117

- 118

- 120

- 122

- 123

- 124

- 126

- 128

- 129

- 130

- 132

- 134

- 135

- 136

- 138

- 140

- 141

- 142

- 144

- 146

- 147

- 148

- 150

- 152

- 154

- 156

- 158

- 159

- 160

- 162

- 164

- 166

- 168

- 170

- 172

- 174

- 176

- 177

- 178

- 180

- 182

- 184

- 186

- 188

- 189

- 190

- 192

- 194

- 195

- 196

- 198

- 200

- 201

- 202

- 204

- 207

- 208

- 210

- 212

- 213

- 214

- 216

- 220

- 222

- 224

- 225

- 226

- 228

- 230

- 231

- 232

- 234

- 236

- 237

- 240

- 242

- 243

- 244

- 246

- 248

- 249

- 250

- 252

- 254

- 255

- 256

- 258

- 260

- 264

- 266

- 267

- 268

- 270

- 273

- 276

- 278

- 280

- 282

- 284

- 285

- 286

- 288

- 290

- 291

- 292

- 294

- 297

- 300

- 302

- 303

- 304

- 308

- 309

- 310

- 312

- 314

- 315

- 318

- 320

- 322

- 324

- 326

- 327

- 328

- 330

- 332

- 333

- 336

- 338

- 339

- 340

- 342

- 344

- 345

- 346

- 348

- 350

- 351

- 352

- 354

- 357

- 358

- 360

- 363

- 366

- 369

- 370

- 372

- 375

- 376

- 378

- 380

- 381

- 382

- 384

- 386

- 387

- 393

- 394

- 396

- 399

- 400

- 402

- 405

- 406

- 408

- 412

- 414

- 417

- 420

- 423

- 426

- 430

- 432

- 436

- 440

- 444

- 446

- 447

- 448

- 452

- 453

- 456

- 459

- 460

- 462

- 470

- 471

- 478

- 480

- 484

- 486

- 488

- 489

- 492

- 494

- 495

- 500

- 501

- 502

- 504

- 506

- 510

- 513

- 516

- 522

- 524

- 525

- 530

- 531

- 537

- 540

- 543

- 544

- 549

- 550

- 552

- 558

- 561

- 564

- 570

- 572

- 576

- 578

- 579

- 582

- 586

- 588

- 591

- 597

- 598

- 600

- 603

- 606

- 609

- 612

- 616

- 618

- 624

- 630

- 633

- 634

- 639

- 642

- 646

- 651

- 654

- 660

- 666

- 670

- 672

- 675

- 676

- 681

- 687

- 690

- 693

- 696

- 699

- 702

- 705

- 708

- 720

- 726

- 729

- 741

- 742

- 744

- 750

- 752

- 756

- 760

- 765

- 772

- 774

- 782

- 783

- 789

- 800

- 810

- 822

- 840

- 852

- 858

- 860

- 866

- 870

- 882

- 892

- 900

- 912

- 924

- 927

- 930

- 936

- 948

- 950

- 960

- 963

- 966

- 972

- 976

- 981

- 993

- 994

- 996

- 1005

- 1008

- 1014

- 1050

- 1059

- 1068

- 1071

- 1086

- 1098

- 1113

- 1137

- 1170

- 1188

- 1212

- 1215

- 1260

- 1290

- 1299

- 1305

- 1326

- 1335

- 1374

- 1386

- 1422

- 1446

- 1521

-

Number of Teeth(Teeth)

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

- 126

- 127

- 128

- 129

- 130

- 131

- 132

- 133

- 134

- 135

- 136

- 138

- 139

- 140

- 141

- 142

- 143

- 144

- 145

- 146

- 147

- 148

- 149

- 150

- 151

- 152

- 153

- 154

- 155

- 157

- 159

- 160

- 161

- 162

- 163

- 164

- 165

- 166

- 167

- 168

- 169

- 170

- 171

- 172

- 173

- 174

- 175

- 176

- 177

- 179

- 180

- 181

- 183

- 184

- 185

- 186

- 187

- 188

- 190

- 191

- 192

- 193

- 194

- 196

- 197

- 199

- 200

- 201

- 203

- 204

- 206

- 208

- 210

- 211

- 213

- 214

- 215

- 217

- 218

- 220

- 222

- 223

- 224

- 225

- 226

- 227

- 229

- 230

- 231

- 233

- 234

- 235

- 236

- 239

- 240

- 242

- 243

- 244

- 246

- 247

- 248

- 250

- 251

- 252

- 253

- 255

- 258

- 261

- 262

- 263

- 265

- 270

- 272

- 274

- 275

- 279

- 280

- 284

- 285

- 286

- 289

- 290

- 293

- 294

- 299

- 300

- 303

- 304

- 308

- 309

- 312

- 315

- 316

- 317

- 320

- 321

- 322

- 323

- 324

- 327

- 330

- 331

- 332

- 335

- 336

- 338

- 345

- 348

- 350

- 351

- 353

- 356

- 357

- 362

- 363

- 366

- 371

- 376

- 379

- 380

- 386

- 390

- 391

- 396

- 400

- 404

- 405

- 420

- 426

- 430

- 433

- 435

- 442

- 445

- 446

- 450

- 458

- 462

- 465

- 474

- 475

- 482

- 488

- 497

- 507

-

Type

- GBN□□□2GT

- GBN□□□3GT

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- Same day

- 7 Days or Less

- 8 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Where does the idler pulleys have to be placed on the timing belt?

-

Answer:

As a rule, the idler pulleys are positioned on the slack side, since the tension of the timing belt is here lowest during operation. Ideally, the timing belt is tensioned from the inside, because this prevents the timing belt from bending alternately. This is particularly recommended for timing belts with a steel tension cord. The idler pulley should always be larger than the smallest timing pulley of the belt drive system.

-

Question:

For what purpose can a timing belt with a round profile be used for?

-

Answer:

Round profile timing belts can be used in many applications. These are well suited for transmitting torque. In addition, the reverse play is very low due to the round profile shape with changing direction of rotation. The timing belts are also well suited for highly precise positioning. Timing belts with a round tooth profile can therefore often be found in 3D printers.

-

Question:

Can multiple belts be used for the transfer?

-

Answer:

A transmission can take place via one or more timing belts. If an equal distribution of the forces across the individual belts is not possible, it must be ensured that one belt alone can withstand the maximum load. In order to enable uniform distribution of forces, a precise adjustment is necessary. For this purpose, a toothed belt disc with clamping sleeve can be used, because it can be adjusted continuously and ensure uniform distribution.

-

Question:

Can a timing belt used for transmission?

-

Answer:

With timing belts, a gear ratio or reduction in a drive is possible. The gear ratio is established based on the number of teeth on the pulleys. It should be ensured that the minimum number of teeth of the timing pulley disc is not undercut.

-

Question:

What is the possible tensile stress for timing belts?

-

Answer:

The maximum allowable tension for MISUMI timing belts depends on the belt type, speed of rotation and belt pulley diameter. For more information, click on this link.

-

Question:

What is the minimum size of timing pulleys?

-

Answer:

The minimum size or the minimum number of teeth of a timing pulley depends on the belt type used and the height of the applied speed or rotation. You can find more detailed information about the minimum number of teeth of timing pulley discs in the selection of Timing Pulleys available as a PDF.

-

Question:

Does a timing belt stretch a lot?

-

Answer:

As opposed to a roller chain, the expansion is small. The length extension of timing belts is very stable. Therefore, it is not absolutely necessary to re-tension the timing belt during operation, as is necessary for chain drives. This makes the timing belt very easy to maintain compared to the chain. However, it should be ensured that the timing belt is free of oil, as the natural rubber could swell.

-

Question:

What is the purpose of a timing belt?

-

Answer:

The primary task of a timing belt is the synchronous and slip-free transmission of force or power. Depending on the task, various profile shapes are available for timing belts. These can be roughly divided into drive, conveying and positioning. In the following overview, you can view the various areas of use: Overview as PDF