- Stan magazynowy

- Pokaż tylko pozycje magazynowe

- Characteristics/Applications

- Module

- 0.5

- 0.8

- 1

- 1.5

- 2

- 2.5

- 3

- Length L(mm)

- 98.01

- 98.96

- 296.88

- 298.45

- 301.59

- 494.8

- 496.37

- 497.63

- 499.51

- 997.45

- 999.02

- 999.03

- Material

- General Steel Material

- EN 1.1191 Equiv.

- Stainless Steel

- EN 1.4301 Equiv.

- Material Details

- Surface Treatment

- Length (nominal)

- 1,000

- 100

- 300

- 500

- Number of Effective Teeth(teeth)

- 39

- 53

- 63

- 79

- 95

- 106

- 120

- 127

- 159

- 192

- 198

- 212

- 318

- Tooth Width W (or D)(mm)

- 3

- 4

- 10

- 15

- 20

- 25

- 30

- End Face Machining

- Provided

- Both Ends Machined Type

- Type

- CAD

- 2D

- 3D

- Szacowane dni wysyłki

- Wszystko

- Możliwa wysyłka tego samego dnia

- W ciągu 7 dni robocze

- W ciągu 9 dni robocze

Rack gears / contact angle 20 degrees / dimension L standard

Numer części:

.Rysunek konturowy i tabela specyfikacji

Dimensional Drawing

| Module | B (Hole Pitch) | M (Coarse) | d1 | d2 | Z1 |

| 0.5 | 180 | — | 3.5 | — | — |

| 0.8 | — | 3.5 | — | — | |

| 1.0 | M3 | 3.5 | 6.5 | 3.5 | |

| 1.5 | M4 | 4.5 | 8 | 4.5 | |

| 2.0 | M5 | 5.5 | 9.5 | 5.5 | |

| 2.5 | M5 | 5.5 | 9.5 | 6.5 | |

| 3.0 | M5 | 5.5 | 9.5 | 5.5 |

| ■Both Ends Machined Type | ||||||

| ||||||

Enlarged View of End Face (Both Ends Machined Type)

| ||||||

| [ ! ] F = L-B× (K-1)2 |

| Metal: L Tolerance (mm) | Plastic: L Tolerance (mm) | W, H Dimension Tolerance (mm) | Accumulated Pitch Error (μm) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | Material | Surface Treatment |

| RGEA | EN 1.1191 Equiv. | Black Oxide |

| RGEAB | Free-cutting brass | - |

| RGEAS | EN 1.4301 Equiv. | - |

| RGEAM | MC Nylon (Blue) | - |

| RGEAP | Polyacetal (White) | - |

[ ! ] Material: MC Nylon and Polyacetal dimensions may change depending on the operating environment.

[ ! ] Flatness (warpage) accuracy is L = 500 or less: 0.2, 501 or more: 0.3.

[ ! ] This product is not hardened.

Specification Table

| Part Number | — | Nominal | — | Hole Machining |

| RGEA1.0 | — | 500 | — | A |

| Part Number | Nominal | Hole Machining | Effective Number of Teeth | L | P (Pitch) | W | H | h | K (Number of Holes) | |

| Type | Module | |||||||||

| RGEA RGEAB RGEAS RGEAM RGEAP | 0.5 | 100 | N (No Hole Machining) KA (Side Through Hole) | 63 | 98.96 | 1.571 | 3 | 9 | 8.5 | — |

| 300 | 192 | 301.59 | 2 | |||||||

| 500 | 318 | 499.51 | 3 | |||||||

| 0.8 | 100 | 39 | 98.01 | 2.513 | 4 | 10 | 9.2 | — | ||

| 300 | 120 | 301.59 | 2 | |||||||

| 500 | 198 | 497.63 | 3 | |||||||

| 1.0 | 100 | N (No Hole Machining) A (Back Tapped) ST (Side Tapped) Z (Side Counterbored) | 30 | 94.25 | 3.142 | 10 | 12 (10) | 11 (9) | — | |

| 300 | 95 | 298.45 | 2 | |||||||

| 500 | 159 | 499.51 | 3 | |||||||

| 1000 | 318 | 999.02 | 6 | |||||||

| RGEA RGEAS RGEAP | 1.5 | 100 | 21 | 98.96 | 4.712 | 15 | 20 (15) | 18.5 (13.5) | — | |

| 300 | 63 | 296.88 | 2 | |||||||

| 500 | 106 | 499.51 | 3 | |||||||

| 1000 | 212 | 999.02 | 6 | |||||||

| 2.0 | 100 | 15 | 94.25 | 6.283 | 20 | 25 (20) | 23 (18) | — | ||

| 300 | 47 | 295.31 | 2 | |||||||

| 500 | 79 | 496.37 | 3 | |||||||

| 1000 | 159 | 999.02 | 6 | |||||||

| 2.5 | 100 | 12 | 94.25 | 7.854 | 25 | 30 (25) | 27.5 (22.5) | — | ||

| 300 | 38 | 298.45 | 2 | |||||||

| 500 | 63 | 494.8 | 3 | |||||||

| 1000 | 127 | 997.4 | 6 | |||||||

| 3.0 | 100 | 10 | 94.25 | 9.425 | 30 | 35 (30) | 32 (27) | — | ||

| 300 | 31 | 292.17 | 2 | |||||||

| 500 | 53 | 499.51 | 3 | |||||||

| 1000 | 106 | 999.02 | 6 | |||||||

Alterations

| Alterations | One End Tapped | Both Ends Tapped | Tapped Hole Dimension Change | ||||||||||||||||||||||||||||||

| Code | MC | WMC | TPC | ||||||||||||||||||||||||||||||

| Spec. | Ordering Code MC5 | Ordering Code WMC5 | Changes the tapped hole dimension. Ordering Code TPC4

| ||||||||||||||||||||||||||||||

|

|  |

| ||||||||||||||||||||||||||||||

| [NG] For RGEAS, M4 is not available for module 1.0. | [NG] For RGEAS, M4 is not available for module 1.0. | ||||||||||||||||||||||||||||||||

General information - Rack Gears

Selection Details of Rack Gears

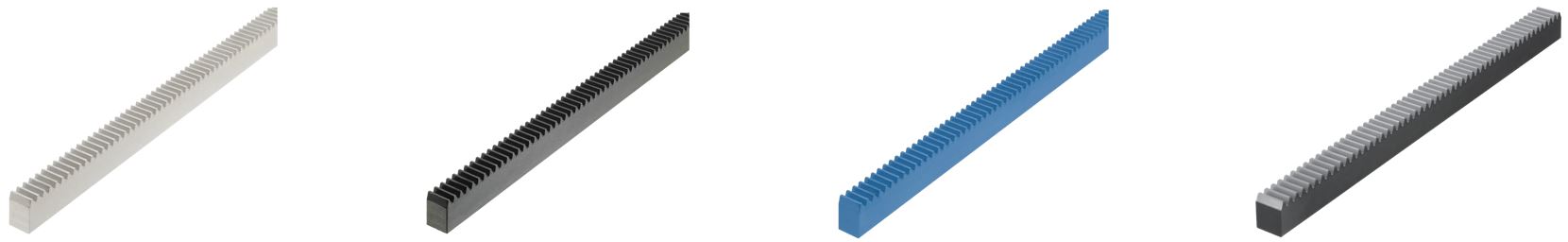

-Material: steel, stainless steel, brass, plastic

-Coatings: uncoated, burnished

-Heat treatment: untreated, surface curing (induction hardened)

-Module: 0.5, 0.8, 1, 1.5, 2, 2.5, 3

-Width: 3 to 30 mm

-Number of teeth: 9 to 192

-Outer diameter (round): 8 to 30 mm

-Length: 20 to 1980 mm

Description / Rack Gear Basics

The rack gear from MISUMI are fundamentally used for motion conversion. The rack gear allows converting a rotary motion into a linear motion or a linear motion into a rotary motion. A rack gear can transmit high forces due to the form-fitting gearing. In connection with a gear wheel or spur gear, a gear rack drive forms a slip-free transmission of force and prevents a slip-through. For a large number of applications, the slip-free transmission of the rack gear is an efficient transmission of force and motion. The rack gear drive also withstands high loads with a compact design. With rack gears, high speeds can also be driven in applications with low noise generation. With MISUMI, you can configure your rack gears individually in length and in other parameters.

During the transfer of motion, the teeth intertwine and largely unroll during the transfer to one another. The rack gear can be used for the transfer of motion almost over the entire length. To prevent the gear wheel from overflowing, for example, stopper bolts or stopper blocks are recommended. Since the module is standardized, it must be ensured for the construction of a rack drive that the same module is used for the rack and the gear wheel. The rack gear allows precise control by directly transmitting motion, torque and speed.

For high wear resistance and reliability, our product range also offers surface-hardened rack gears. The hardened rack gear has a harder surface of the teeth, which makes it less susceptible to wear and tear. Their long service life helps reduce production downtime. Hardened rack gears are also less susceptible to locking-related play and retain their precision in the long term. This aspect makes hardened rack gears particularly recommended for precise applications.

A rack gear drive has a low backlash. In general, the tooth flank clearance is used for assembly and thermal expansion. Like the head play, it can serve as a gap for lubricants. For very precise applications, the reverse play is not beneficial. In order to minimize this during precision applications, pre-tensioning is required. On lifting tables, the dead weight already generates a vertical pretension in the rack gear, which minimizes the reverse play. If the rack gear is aligned horizontally, a separate pretension should be used to reduce the reverse play. This can be achieved with tension springs or other exciting components, for example. When selecting a suitable rack gear, the first decision criterion is the material of the rack gear drive. The following are some advantages of the rack gear materials:

Steel rack gears

Rack gears made of steel have high strength and withstand high loads. Therefore, steel rack gears are suitable for heavy loads. The material surface can be hardened to increase wear resistance. This makes the rack gear resistant and durable. In addition, steel is very heat-resistant and is suitable for applications in which high ambient temperatures occur. One disadvantage of steel is its low corrosion resistance.

Stainless steel rack gears

Stainless steel rack gears are highly corrosion resistant, since stainless steel forms a passive layer (oxide layer). This makes them suitable for applications where higher humidity is found. Furthermore, stainless steel offers good chemical resistance. Like steel, stainless steel is temperature resistant without losing strength. High temperatures can cause discoloration (tempering colour) in stainless steel. However, this does not affect the function in any way. Similar to the steel, stainless steel is robust and has a long service life. Another advantage is that rack gears made of stainless steel have hygienic properties. Therefore, this material is often used in the pharmaceutical industry and in medical technology.

Brass rack gears

Brass rack gears are well protected against corrosion. Therefore, a brass rack gear is well suited in corrosive environments. Depending on the application, it can be advantageous that brass does not tend to spark when abrasion is applied. In addition, brass has a high strength and ductility. This allows the material to deform before it breaks. Brass rack gears have a high thermal conductivity, which allows heat to be dissipated similar to a heat sink. The perhaps most important property of the brass rack gear is its gliding property. In the case of a lubrication film dissipates, this property serves as a certain fail-safe.

Lubrication of rack gears

The lubrication of the rack gear is decisive for low-wear operation. The lubrication reduces the friction on the tooth flanks of the rack gear and the pinion, which reduces the material abrasion. In this way, proper lubrication of the rack gear increases the service life, performance and ensures long-term precision. In principle, a rack can be lubricated with grease or oil. The type of lubrication that is suitable depends on several factors such as temperature, load and speed. Grease lubrication is often used for high loads and torques, while oil lubrication is used for high speeds. Lubricant manufacturers offer a suitable lubricant for almost all load cases. Before re-lubricating, the tooth drive should be thoroughly cleaned to prevent damage to the tooth flanks or teeth from contamination. Depending on the application, the lubricant can be sprayed, brushed, or sprayed onto the rack gear. The lubrication intervals must be selected depending on the application and the lubricant used. It is always recommended to adjust the lubrication intervals to the given circumstances.

Application examples - Rack Gears

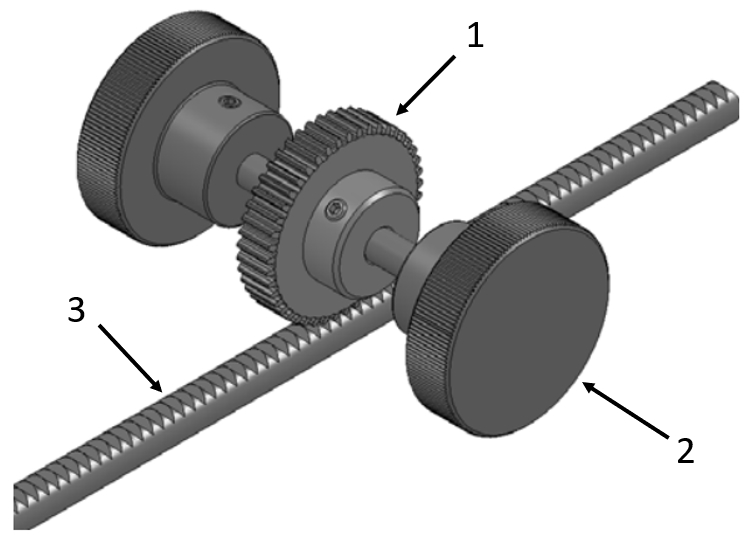

Application example - rack gear with spur gear

(1) Spur gear, (2) Clamping knobs, (3) Rack gear

Industrial applications

Lista numerów części

| Numer części |

|---|

Cena jednostkowa (bez VAT)(Cena jednostkowa z podatkiem) | Standardowa data wysyłki |

|---|

52.33 € ( 62.27 € ) | 7 dni robocze |

84.42 € ( 100.46 € ) | 7 dni robocze |

89.45 € ( 106.45 € ) | 7 dni robocze |

121.88 € ( 145.04 € ) | 7 dni robocze |

114.53 € ( 136.29 € ) | 7 dni robocze |

50.81 € ( 60.46 € ) | 7 dni robocze |

75.90 € ( 90.32 € ) | 7 dni robocze |

75.66 € ( 90.04 € ) | Towar dostępny w magazynie – 1 dzień roboczyDostępne z opcją wysyłki tego samego dnia |

117.39 € ( 139.69 € ) | 7 dni robocze |

110.03 € ( 130.94 € ) | 7 dni robocze |

66.17 € ( 78.74 € ) | 7 dni robocze |

54.54 € ( 64.90 € ) | 7 dni robocze |

66.17 € ( 78.74 € ) | 7 dni robocze |

67.19 € ( 79.96 € ) | 7 dni robocze |

92.36 € ( 109.91 € ) | 7 dni robocze |

80.60 € ( 95.91 € ) | 7 dni robocze |

92.36 € ( 109.91 € ) | 7 dni robocze |

99.58 € ( 118.50 € ) | 7 dni robocze |

208.77 € ( 248.44 € ) | 9 dni robocze |

156.26 € ( 185.95 € ) | 9 dni robocze |

208.77 € ( 248.44 € ) | 9 dni robocze |

223.95 € ( 266.50 € ) | 9 dni robocze |

99.32 € ( 118.19 € ) | 7 dni robocze |

87.69 € ( 104.35 € ) | 7 dni robocze |

99.32 € ( 118.19 € ) | 7 dni robocze |

100.34 € ( 119.40 € ) | 7 dni robocze |

135.14 € ( 160.82 € ) | 7 dni robocze |

123.35 € ( 146.79 € ) | 7 dni robocze |

135.14 € ( 160.82 € ) | 7 dni robocze |

142.35 € ( 169.40 € ) | 7 dni robocze |

285.83 € ( 340.14 € ) | 7 dni robocze |

263.05 € ( 313.03 € ) | 7 dni robocze |

285.83 € ( 340.14 € ) | 7 dni robocze |

301.01 € ( 358.20 € ) | 7 dni robocze |

143.36 € ( 170.60 € ) | 7 dni robocze |

131.96 € ( 157.03 € ) | 7 dni robocze |

143.36 € ( 170.60 € ) | 7 dni robocze |

150.96 € ( 179.64 € ) | 7 dni robocze |

374.38 € ( 445.51 € ) | 7 dni robocze |

351.62 € ( 418.43 € ) | 7 dni robocze |

374.38 € ( 445.51 € ) | 7 dni robocze |

389.58 € ( 463.60 € ) | 7 dni robocze |

187.62 € ( 223.27 € ) | 7 dni robocze |

176.26 € ( 209.75 € ) | 7 dni robocze |

187.62 € ( 223.27 € ) | 7 dni robocze |

195.23 € ( 232.32 € ) | 7 dni robocze |

464.73 € ( 553.03 € ) | 7 dni robocze |

441.95 € ( 525.92 € ) | 7 dni robocze |

464.73 € ( 553.03 € ) | 7 dni robocze |

479.91 € ( 571.09 € ) | 7 dni robocze |

255.84 € ( 304.45 € ) | 7 dni robocze |

244.19 € ( 290.59 € ) | 7 dni robocze |

232.80 € ( 277.03 € ) | 7 dni robocze |

240.40 € ( 286.08 € ) | 7 dni robocze |

Szczegółowe informacje

Kontury i specyfikacja

Specifications/Overview

MISUMI Rack Gears (Both Ends Machined Type) are end machined with negative pitch tolerance in length.

When connecting the racks, use a piece of rack (rack gear in the same module) as a spacer jig as shown in the right side figure to properly adjust the pitch.

Rack Gear Flatness Measurement Method

Rack Gear Flatness Measurement MethodMeasure the gap with the rack gear teeth facing up and both ends grounded.

Flatness Tolerance

0.2 for L = 500 or less

0.3 for L = 501 or more