- Belt Width(mm)

- 10

- 15

- 20

- 25

- [T] Number of Teeth

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 72

- Material

- Aluminum

- 2000 Series Aluminum Alloy (Duralumin)

- Aluminum Alloy

- Surface Treatment

- [Y] Shaft Bore Specification (Both Ends Stepped Hole)(mm)

- 5

- 6

- 7

- 8

[5–83/1mm jedn.] - [N] Shaft Bore Specification (New JIS Keyway Hole + Tap)(mm)

- 8

- 10

- 11

- 12

- 13

- 55

[10–55/1mm jedn.] - [C] Shaft Bore Specification (Old JIS Keyway Hole + Tap)(mm)

- 10

- 12

- 15

- 16

- 18

- 19

- 20

- [P] Shaft Bore Specification (Round Hole + Tap)(mm)

- 5

- 6

- 6.35

- 7

- 8

[5–70/1mm jedn.] - [H] Shaft Bore Specification (Round Hole)(mm)

- 6.35

[5–85/1mm jedn.] - [NK] Shaft Bore Specification (Shaft Bore Dia. 10 Keyway Width 4mm Height 1.8mm)(mm)

- 10

- [V] Shaft Bore Specification (Stepped Hole)(mm)

- 5

- 6

- 6.35

- 7

- 8

[5–84/1mm jedn.] - [F] Shaft Bore Specification (Stepped Hole: Counterbored Holes on the Hub Side)(mm)

- 5

- 6

- 6.35

- 7

- 8

[5–84/1mm jedn.] - [WB] Shaft Bore Specification (Two-Stepped Hole on one side)(mm)[5–83/1mm jedn.]

- Type

- CAD

- 2D

- 3D

- Szacowane dni wysyłki

- Wszystko

- W ciągu 6 dni robocze

- W ciągu 8 dni robocze

- W ciągu 10 dni robocze

- W ciągu 14 dni robocze

Timing Belt Pulleys / S5M / Flanged Pulley Selectable / Configurable / Material Selectable / Treatment Selectable(Lista numerów części: str. 4)

Numer części:

.Rysunek konturowy i tabela specyfikacji

Back to the Category Toothed Pulleys/Timing Pulleys/Idler Pulleys

Technical Drawing - Toothed Pulleys/Timing Pulleys/Idler Pulleys

● Pulley Shape

Shape A

Shape B

Standard Tooth Profile

[ ! ]

[ ! ]

Available dimensions and tolerances can be found under the tab More Information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| mm | Nominal | |||

| S5M100 | S5M150 | S5M200 | S5M250 | |

| A | 11 | 17 | 22 | 27 |

| W | 16 | 22 | 27 | 32 |

| L | 28 | 34 | 39 | 44 |

| dH7 Shaft Bore I.D. | M (Coarse) | Accessory Set Screws |

| 5 | M3 | M3 × 3 |

| 6 to 12 | M4 | M4 × 3 |

| 13 to 17 | M5 | M5 × 4 |

| 18 to 30 | M6 | M6 × 5 |

| 31 to 45 | M8 | M8 × 6 |

| 46 to 70 | M10 | M10 × 8 |

[ ! ] Shaft Bore Specs. H (Round hole), V or F (Stepped Hole), Y (Both Sides Stepped Hole) and WB (Two-stepped Hole) do not have tapped holes.

[ ! ] The tolerance of the tap position dimension from the boss end face and pulley end face is ±0.3.

[ ! ] Unless otherwise specified except for teeth and F dimensions, the dimension tolerance conforms to JIS B 0405 Class m.

H round hole

P Round Hole + Tap

[ ! ] For A-Shape pulley, the screw holes are

set at around 120° to keep away from peaks.

N New JIS Keyway + Tap

C Old JIS Keyway + Tap

V Stepped Hole

[ ! ] Z - d ≥ 2

[ ! ] 2.0 ≤ J ≤ W-2.0

F Stepped Hole

(Counterbored Hole on the Hub Side)

[ ! ] Applicable to Shape B only

[ ! ] Z - d ≥ 2

[ ! ]2.0 ≤ J ≤ L-2.0

Y Both Ends Stepped Hole

[ ! ] Applicable to Shape A only

[ ! ]Q (R)-Y ≥ 2

[ ! ]S+T ≤ W-3.0

[ ! ]S (T) ≥ 3.0

WB Two-stepped hole

[ ! ] Applicable to Shape A only

[ ! ] Q-R ≥ 2

[ ! ] R-WB ≥ 2

[ ! ] S+T ≤ W-3.0

[ ! ] S (T) ≥ 3.0

| Type | Belt Width | [M] Material | [S] Surface Treatment | [A] Accessory Set Screws | ||||

| 10 mm | 15 mm | 20 mm | 25 mm | Pulley | Flange | |||

| S5M100 | S5M150 | S5M200 | S5M250 | |||||

| HTPA | ● | ● | ● | ● | Aluminum alloy | Aluminum alloy | Clear Anodize | EN 1.4301 Equiv. |

| HTPB | ● | ● | ● | ● | Black Anodize | |||

| HTPK | ● | ● | ● | ● | Hard Clear Anodize | |||

| HTPN | ● | ● | ● | ● | Electroless nickel plating | |||

| HTPT | ● | ● | ● | ● | EN 1.1191 Equiv. | EN 1.0330 Equiv. | — | EN 1.7220 Equiv. (Black Oxide) |

| HTPM | ● | ● | ● | ● | Black Oxide Coating | |||

| HTPP | ● | ● | ● | ● | Electroless nickel plating | |||

| HTPS | ● | ● | ● | ● | EN 1.4301 Equiv. | EN 1.4301 Equiv. | — | EN 1.4301 Equiv. |

N: New JIS (B1301) Keyway Dimensions

| C: Old JIS keyway Dimensions

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ay Dimensions |

Further specifications can be found under the tab More Information.

Composition of a Product Code - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | — | Pulley Shape | — | Shaft Bore Specs.: I.D. | — | Z | — | J | — | Q | — | R | — | S | — | T | |

| (Shaft Bore Specs.: H, P, N, C) | HTPA20S5M150 | — | B | — | NK10 | ||||||||||||

| (Shaft Bore Specs.: V, F) | HTPA26S5M150 | — | A | — | V10 | — | Z23 | — | J16.0 | ||||||||

| (Shaft Bore Specs.: Y, WB) | HTPA40S5M250 | — | A | — | Y17 | — | Q35 | — | R35 | — | S10 | — | T10 |

Alterations - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | — | Pulley Shape | — | Shaft Bore Specs.: I.D. | — | Z | — | J | — | Q | — | R | — | S | — | T | — | (KC90, etc.) | |||||

| HTPM60S5M150 | — | A | — | H30 | — | KSC50 | |||||||||||||||||

| Alterations | Set Screw Angle Change | No Flange | Single Flange | Flange Cut |

| Code | KC90 | NFC | RFC·LFC | FC |

| Spec. | Changes an angle of set screw to 90°. [ ! ] For A-Shape pulley, the screw holes are set at around 90° to keep away from peaks.  | (Flange 2 pcs. Included) Ordering Code NFC  | (Flange 1 pc. Included) Ordering Code RFC  | Cut the flange O.D. in 0.5 mm increments. Ordering Code FC17 Application Notes [ ! ]FC ≥ (O.D.) +1 [ ! ]FC ≤ F-2 [ ! ] No surface treatment is applied on flange circumference.  |

| Alterations | Retaining Ring Groove | Taper for Bearing Holder | Hub Shortening | Tapped Hole Dimensions | Included Set Screw Length Change | ||||||||||||||||||||||||||||

| Code | SRG | BTC | BC | TPC | SLH | ||||||||||||||||||||||||||||

| Spec. | Retaining Ring Groove applicable to the shaft dia. of stepped hole is machined. Specify SRG 2.5-24.5 mm  | Taper for retaining bearing inner ring Ordering Code BTC6-TL1.5  | Cuts the hub length in 0.5 mm increments. Ordering Code BC6.5 Application Notes [!] Shaft Bore Specs.  | Ordering Code TPC5 Application Notes [ ! ] Applicable to Shaft Bore Specs. P, N, C only

| Ordering Code SLH10 Application Notes [ ! ] Applicable to Shaft Bore Specs. P, N, C only

|

| Alterations | Add Side Holes [!] Conditions may vary depending on the shaft bore specs. | ||

| Side Tapped Hole | Side Through Hole | Side Counterbored | |

| Code | QTC·QFC·QSC | KTC·KFC·KSC | ZTC·ZFC·ZSC |

| Spec. | Machines tapped hole on the side surface of hub side. Ordering Code QTC28−M4 Q□C Selection Specify the hole position (P. C. D. dim.). M Selection M3, M4, M5, M6, M8 Application Notes [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) | Machines through hole on the side surface. Ordering Code KTC28−K4.5 K□C Selection Specify the hole position (P. C. D. dim.). Specify K K4.0 to 13.0 (0.5 mm Increments) Application Notes [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) | Machines counterbored hole on the side surface. Ordering Code ZTC28−ZM4 Z□C Selection Specify the hole position (P. C. D. dim.). ZM Selection ZM3, ZM4, ZM5, ZM6, ZM8 Application Notes [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) |

Here to the Overview of Options as PDF.

General Information - Toothed Pulleys/Timing Pulleys/Idler Pulleys

Selection details of toothed pulleys/timing pulleys/idler pulleys

- Material: aluminum, steel, stainless steel (stainless steel), plastic

- Coatings: uncoated, burnished, anodized, nickel-plated

- Profile form: 1.5GT, 2GT, 3GT, 5GT, P2M, P3M, P5M, P8M, S2M, S3M, S5M, S8M, S14M, T2.5, T5, T10, AT5, AT10, 5M, 8M, 14M, 8YU, H, L, MXL, XL, PowerGrip GT3: MR2, MR3, MR5

- ISO tolerances: H7

- Belt width (mm): 4, 4.8, 6, 6.4, 7, 7.9, 9, 9.5, 10, 12, 12.7, 15, 18, 19.1, 20, 25, 25.4, 26, 28, 30, 31, 38,1, 40, 50, 50.8, 53, 60, 74, 76.2, 100

- Belt width (inches): 0.19, 0.25, 0.31, 0.37, 0.5, 0.75, 1, 1.5, 2

- Number of teeth: 10 to 72

Description/Basics

The toothed pulley for mechanical engineering is intended for the transmission of force and torque. Timing pulleys enable a gear ratio of speeds through belt pulleys of different sizes. Timing pulleys are more efficient, durable and significantly more maintenance-friendly compared to chain transmissions.

How much torque and load a timing pulley can transmit depends on the width of the belt. The width of the belt must be calculated. It is recommended to ensure the belt is correctly tensioned. MISUMI already offers the suitable idler pulley and return rollers with integrated ball bearings. For design and design help follow this link.

Different profile shapes of the toothed belts and belt pulleys are responsible for the transmission of power. Depending on the positioning accuracy, the applied torque and the conveying weight, MISUMI offers the fitting pulley. Toothed belt drives are generally used in the industry in three areas:

Positioning: Timing pulleys is often used in 3D printers. A toothed pulley with a semi-circular profile (e.g., GT) is often used for the required position accuracy of a 3D printers. The round shape offers the benefit of little play when the direction changes.

Drive: toothed pulleys are also used for high torque. In most cases, a timing pulley with a rounded trapezoidal profile (e.g., S8M) is used. These are particularly well suited for the transmission of high forces, which occur in drives of various applications in order to drive mechanical components.

Conveying: toothed pulleys can also be used for transporting loads. A straight trapezoidal profile is often used for this purpose (e.g., AT). This toothed pulley shape offers a large surface for loading and transmitting of loads.

Which toothed pulley or timing pulley is the right one for your application depends on the respective task of the toothed belt drive. Different toothed disc profiles have proven themselves for each type of application.

Various bore hole shapes and fastening variants are available for shaft mounting. These allow fastening via set screws, keyways and by means of Mecha locks. Fastening via a clamping sleeve has the further advantage that it allows adjusting the alignment continuously. The MISUMI product assortment has these ready-to-install.

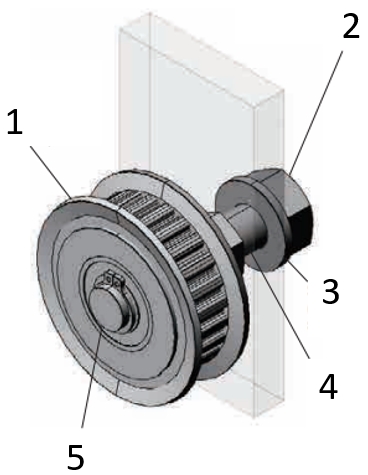

Application Examples - Toothed Pulleys/Timing Pulleys/Idler Pulleys

Application example: idler pulley

(1) Idler pulleys, (2) chain tensioner

Application example: deflection roller

S (1) Toothed pulleys with crimp disc, (2) nut, (3) washer, (4) cantilever shaft, (5) retaining ring

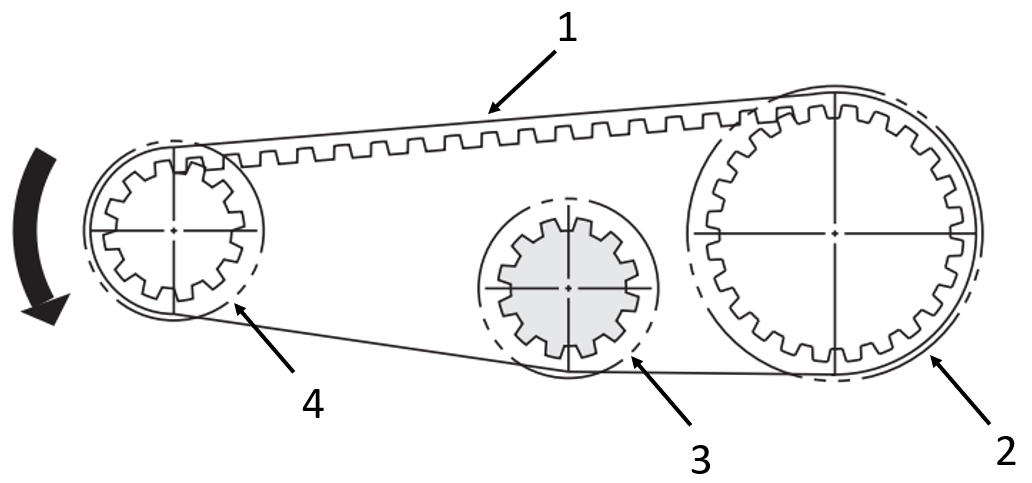

Application example: timing pulleys

(1) Flat head screw, (2) Timing pulley, (3) Timing belt, (4) Screw-on terminal

Application example: of toothed belt drives

(1) Toothed belt, (2) driven toothed pulley with crimp disc, (3) idler pulley with crimp disc, (4) driving toothed pulley with crimp disc

Industrial Applications

Lista numerów części

| Numer części |

|---|

Cena jednostkowa (bez VAT)(Cena jednostkowa z podatkiem) | Standardowa data wysyłki |

|---|

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 6 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

- ( - ) | 8 dni robocze |

Szczegółowe informacje

Podstawowe informacje

Przestroga

- Please note that the swaged flange options, NFC, RFC, and LFC, are not reflected in the CAD data.

Kontury i specyfikacja

Back to the Category Toothed Pulleys/Timing Pulleys/Idler Pulleys

Technical Drawing - Toothed Pulleys/Timing Pulleys/Idler Pulleys

● Pulley Shape

Shape A

Shape B

Standard Tooth Profile

[ ! ]

[ ! ]

Specification Tables - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | Pulley Shape | Pulley Shape | P.D. | O.D | D | F | E | |||||||

| Type | Number of Teeth | Type Nominal Width | A | B | ||||||||||

| Shaft Bore Specs. | ||||||||||||||

| H Round Hole V·Y·WB Stepped Hole | P Round Hole Tapped | N·C Keyway Tapped | H Round Hole V·F Stepped Hole | P Round Hole Tapped | N·C Keyway Tapped | |||||||||

| d1 mm increments / Selectable | ||||||||||||||

| Aluminum HTPA HTPB HTPK HTPN Steel HTPT HTPM HTPP Stainless Steel HTPS | 14 | S5M100 S5M150 S5M200 S5M250 | A B | 5 to 12 | 5 to 10 | 8·10 | 5 to 10 | 5 to 8 | — | 22.28 | 21.32 | 14 | 26 | 16 |

| 15 | 5 to 14 | 5 to 11 | 23.87 | 22.91 | 15 | 28 | 18 | |||||||

| 16 | 5 to 16 | 5 to 12 | 8 to 12 | 5 to 13 | 5 to 10 | 8 | 25.46 | 24.50 | 17 | 32 | 20 | |||

| 17 | 27.06 | 26.10 | ||||||||||||

| 18 | 6 to 18 | 6 to 12 | 6 to 15 | 6 to 11 | 8·10 | 28.65 | 27.69 | 19 | 33 | 22 | ||||

| 19 | 6 to 20 | 6 to 16 | 8 to 16 | 30.24 | 29.28 | 36 | 24 | |||||||

| 20 | 31.83 | 30.87 | ||||||||||||

| 21 | 7 to 23 | 7 to 18 | 8 to 18 | 7 to 20 | 7 to 16 | 8 to 12 | 33.42 | 32.46 | 24 | 40 | 27 | |||

| 22 | 35.01 | 34.05 | ||||||||||||

| 23 | 7 to 26 | 7 to 20 | 8 to 20 | 7 to 23 | 7 to 17 | 8 to 13 | 36.61 | 35.65 | 27 | 45 | 30 | |||

| 24 | 38.20 | 37.24 | ||||||||||||

| 25 | 8 to 15 | 39.79 | 38.83 | |||||||||||

| 26 | 8 to 31 | 8 to 23 | 8 to 22 | 8 to 27 | 8 to 21 | 8 to 17 | 41.38 | 40.42 | 31 | 48 | 35 | |||

| 27 | 8 to 24 | 8 to 24 | 8 to 28 | 8 to 22 | 8 to 18 | 42.97 | 42.01 | 32 | ||||||

| 28 | 44.56 | 43.60 | ||||||||||||

| 29 | 10 to 32 | 10 to 26 | 10 to 26 | 10 to 29 | 10 to 23 | 10 to 18 | 46.15 | 45.19 | 33 | 52 | 36 | |||

| 30 | 47.75 | 46.79 | ||||||||||||

| 31 | 10 to 36 | 10 to 28 | 10 to 28 | 10 to 33 | 10 to 27 | 10 to 22 | 49.34 | 48.38 | 37 | 55 | 40 | |||

| 32 | 50.93 | 49.97 | ||||||||||||

| 33 | 52.52 | 51.56 | 58 | |||||||||||

| 34 | 10 to 41 | 10 to 33 | 10 to 33 | 10 to 36 | 10 to 30 | 10 to 25 | 54.11 | 53.15 | 40 | 61 | 45 | |||

| 35 | 55.70 | 54.74 | ||||||||||||

| 36 | 57.30 | 56.34 | ||||||||||||

| 37 | 10 to 46 | 10 to 38 | 10 to 38 | 10 to 43 | 10 to 35 | 10 to 28 | 58.89 | 57.93 | 47 | 67 | 50 | |||

| 38 | 60.48 | 59.52 | ||||||||||||

| 39 | 62.07 | 61.11 | ||||||||||||

| 40 | 63.66 | 62.70 | ||||||||||||

| 41 | 12 to 52 | 12 to 40 | 12 to 38 | 12 to 44 | 12 to 36 | 12 to 30 | 65.25 | 64.29 | 48 | 70 | 56 | |||

| 42 | 66.85 | 65.89 | ||||||||||||

| 43 | 12 to 54 | 12 to 42 | 12 to 40 | 12 to 46 | 12 to 38 | 12 to 32 | 68.44 | 67.48 | 50 | 74 | 58 | |||

| 44 | 70.03 | 69.07 | ||||||||||||

| 45 | 12 to 56 | 12 to 43 | 12 to 40 | 12 to 52 | 12 to 40 | 12 to 36 | 71.62 | 70.66 | 56 | 80 | 60 | |||

| 46 | 73.21 | 72.25 | ||||||||||||

| 47 | 74.80 | 73.84 | ||||||||||||

| 48 | 12 to 59 | 12 to 45 | 12 to 56 | 12 to 45 | 12 to 40 | 76.39 | 75.43 | 60 | 83 | 63 | ||||

| 49 | 77.99 | 77.03 | ||||||||||||

| 50 | 12 to 63 | 12 to 50 | 12 to 43 | 12 to 59 | 12 to 47 | 12 to 43 | 79.58 | 78.62 | 63 | 87 | 67 | |||

| 51 | 81.17 | 80.21 | ||||||||||||

| 52 | 82.76 | 81.80 | ||||||||||||

| 53 | 12 to 71 | 12 to 45 | 12 to 66 | 12 to 48 | 12 to 45 | 84.35 | 83.39 | 70 | 95 | 75 | ||||

| 54 | 85.94 | 84.98 | ||||||||||||

| 55 | 87.54 | 86.58 | ||||||||||||

| 56 | 12 to 76 | 12 to 50 | 12 to 71 | 12 to 50 | 12 to 50 | 89.13 | 88.17 | 75 | 99 | 80 | ||||

| 57 | 90.72 | 89.76 | ||||||||||||

| 58 | 92.31 | 91.35 | ||||||||||||

| 59 | 93.90 | 92.94 | ||||||||||||

| 60 | 95.49 | 94.53 | ||||||||||||

| 72 | 12 to 85 | 12 to 70 | 12 to 55 | 12 to 80 | 12 to 70 | 12 to 55 | 114.59 | 113.63 | 90 | 119 | 100 | |||

| [ ! ]Shaft Bore Dia.6.35 is selectable for Shaft Bore Specs. H, P, V, and F. [NG] Shaft Bore Dia. 9, 51 to 54 are not available for Shaft Bore Spec. N. [NG] Shaft Bore Dia. 8, 11, 13, 14, 17, or 21 to 55 are not available for Shaft Bore Spec. C. | ||||||||||||||

Alterations - Toothed Pulleys/Timing Pulleys/Idler Pulleys

| Part number | — | Pulley Shape | — | Shaft Bore Specs.: I.D. | — | Z | — | J | — | Q | — | R | — | S | — | T | — | (KC90, etc.) | |||||

| HTPM60S5M150 | — | A | — | H30 | — | KSC50 | |||||||||||||||||

| Alterations | Set Screw Angle Change | No Flange | Single Flange | Flange Cut |

| Code | KC90 | NFC | RFC·LFC | FC |

| Spec. | Changes an angle of set screw to 90°. [ ! ] For A-Shape pulley, the screw holes are set at around 90° to keep away from peaks.  | (Flange 2 pcs. Included) Ordering Code NFC  | (Flange 1 pc. Included) Ordering Code RFC  | Cut the flange O.D. in 0.5 mm increments. Ordering Code FC17 Application Notes [ ! ]FC ≥ (O.D.) +1 [ ! ]FC ≤ F-2 [ ! ] No surface treatment is applied on flange circumference.  |

| Alterations | Retaining Ring Groove | Taper for Bearing Holder | Hub Shortening | Tapped Hole Dimensions | Included Set Screw Length Change | ||||||||||||||||||||||||||||

| Code | SRG | BTC | BC | TPC | SLH | ||||||||||||||||||||||||||||

| Spec. | Retaining Ring Groove applicable to the shaft dia. of stepped hole is machined. Specify SRG 2.5-24.5 mm  | Taper for retaining bearing inner ring Ordering Code BTC6-TL1.5  | Cuts the hub length in 0.5 mm increments. Ordering Code BC6.5 Application Notes [!] Shaft Bore Specs.  | Ordering Code TPC5 Application Notes [ ! ] Applicable to Shaft Bore Specs. P, N, C only

| Ordering Code SLH10 Application Notes [ ! ] Applicable to Shaft Bore Specs. P, N, C only

|

| Alterations | Add Side Holes [!] Conditions may vary depending on the shaft bore specs. | ||

| Side Tapped Hole | Side Through Hole | Side Counterbored | |

| Code | QTC·QFC·QSC | KTC·KFC·KSC | ZTC·ZFC·ZSC |

| Spec. | Machines tapped hole on the side surface of hub side. Ordering Code QTC28−M4 Q□C Selection Specify the hole position (P. C. D. dim.). M Selection M3, M4, M5, M6, M8 Application Notes [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) | Machines through hole on the side surface. Ordering Code KTC28−K4.5 K□C Selection Specify the hole position (P. C. D. dim.). Specify K K4.0 to 13.0 (0.5 mm Increments) Application Notes [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) | Machines counterbored hole on the side surface. Ordering Code ZTC28−ZM4 Z□C Selection Specify the hole position (P. C. D. dim.). ZM Selection ZM3, ZM4, ZM5, ZM6, ZM8 Application Notes [ ! ] Minimum Thickness: 2 mm [!] Conditions may vary depending on the shaft bore specs.  (6 Locations) (4 Locations) (3 Locations) |

Here to the Option Overview PDF