Polyurethane rubber bumper / with countersunk hole (Part Numbers - CAD Download)

- Promotional pricing ends 30/11/2024

- Volume Discount

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

- Technical Information

Back to the Category Discs/Sleeves (Rubber, Caoutchouc, Foam, Felt)

Technical Drawing - Polyurethane Rubber Washers

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Polyurethane Rubber Washers

| Type | Urethane only | With Collar | Material | Hardness | Color | ||

| Black Oxide | Electroless Nickel Plating | EN 1.4301 Equiv. | |||||

| L Selectable | AZXSK | AZXSC | AZXSM | AZXSS | Standard Urethane (Ether Polyurethane) | Shore A95 | Natural Color |

| AZXHK | AZXHC | AZXHM | AZXHS | Shore A90 | |||

| AZXMK | AZXMC | AZXMM | AZXMS | Standard Urethane (Ester Polyurethane) | Shore A70 | ||

| AZXLK | AZXLC | AZXLM | AZXLS | Shore A50 | |||

| AZEXHK | AZEXHC | - | - | Abrasion Resistant Urethane | Shore A90 | Dark Brown | |

| AZEXMK | AZEXMC | - | - | Shore A70 | |||

| AZXHHK | AZXHHC | - | - | Heat Resistant Urethane | Shore A90 | Brown | |

| L Configurable | AZXS | AZCS | AZCS-M | AZCS-S | Standard Urethane (Ether Polyurethane) | Shore A95 | Natural Color |

| AZXH | AZCH | AZCH-M | AZCH-S | Shore A90 | |||

| AZXM | AZCM | AZCM-M | AZCM-S | Standard Urethane (Ester Polyurethane) | Shore A70 | ||

| AZXL | AZCL | AZCL-M | AZCL-S | Shore A50 | |||

Further specifications can be found under the tab More information.

Composition of a Product Code - Polyurethane Rubber Washers

| Part Number | - | L | - | M | - | H1 |

| AZXMC25 AZXL50 AZCM40 | - - - | 20 96 70 | - - - | M6 M10 M10 | - | 20 |

General Information - Polyurethane Rubber Washers

Selection details of rubber discs/rubber sleeves

- Material: heat-resistant antistatic, abrasion-resistant, highly abrasion-resistant, low-impact polyurethane rubber (PU/PUR), Vulkollan, ceramic polyurethane rubber, nitrile rubber sponge (NBR), chloroprene rubber (CR), ethylene cautchouc (EPDM), silicone rubber (SI), fluoro-cautchouk (FPM), hard rubber, butyl rubber (IIR), natural rubber, nitrile rubber foam, chloroprene rubber foam, polyethylene foam (EPDM foam), EPT sealing material, Silicone rubber foam, fluoro-rubber foam, special polyurethane foam (SOFRAS), polyester felt, polyester felt

- Hardness: Asker C5 to C35, Asker F75 to F85, Shore A15 to A95

- Versions: disc with bore holes, sleeves with holes, sleeves without holes, sleeves with counterbores, sleeves with external threads, sleeves with collar, dampers with round tip, dampers with conical tip

- Inner diameter: up to 80 mm

- Outer diameter: 6 to 100 mm

- Length: 1 to 10 mm (discs), 10 to 500 mm (sleeves)

Description/Basics

Rubber discs and rubber sleeves, also called rubber buffers, are generally used for vibration damping and impact damping. Rubber sleeves are often used as stopper buffers in industry. Rubber discs are occasionally also used as seals.

Discs and sleeves made of natural rubber are offered in different materials and hardnesses.

While rubber discs are often used for sealing, rubber sleeves are increasingly used as rubber buffers, stopper buffers, or elastomer dampers. MISUMI already offers such a rubber sleeve as a rubber buffer with external thread or counterbore for fastening.

The rubber buffer is also available with a vulcanized metal collar, which not only allows for a firm assembly, but also sits in the anti-backlash rubber sleeve. These adhesives are also available separately. In addition to the material of the rubber buffer, the shape of the stopper buffer is also responsible for the damping characteristic. conical or rounded rubber buffers can also develop a progressive damping curve that generates increasing damping.

Depending on the application and environmental influences, MISUMI offers rubber discs and rubber sleeves in various basic materials with the appropriate resistance. An overview of the intended uses of the respective natural rubber can be found under Natural Rubber Properties as PDF .

The rubber buffers made of polyurethane rubber are also available in an antistatic version. The specific resistance of antistatic rubber discs and rubber sleeves prevents static charging. This can prevent damage to electronic components.

For high temperature applications, MISUMI offers heat-resistant polyurethane rubber, which can withstand temperatures of approx. +120°C (see Specifications for further information).

Vulkollan, on the other hand, is a very abrasion-resistant polyurethane, the abrasion resistance of which is six times higher compared to conventional polyurethane.

Ceramic polyurethane washers and sleeves contain ceramic particles. Despite a low Shore hardness, they can be machined to give them a smooth surface.

MISUMI also offers foam discs and foam sleeves. In addition to damping, these can also have sealing properties. This is achieved by the foam discs due to the closed or semi-closed pores (EPT sealer) inside the material. For semi-closed pores, the pores are sealed under load. Therefore, the type of pores must always be observed for foams in order to select the appropriate foam depending on the application. You can get help for your selection by following this link.

Further properties of natural rubbers and foams can be found in the Properties PDF.

In addition to the aforementioned basic materials, the MISUMI online shop also offers felt discs and felt sleeves. Felt has the properties of capillary action and can absorb and release liquids such as oil. In addition, felt is gentle on sensitive surfaces and is often used for polishing surfaces.

A antivibration materials can also be used for two-sided mounting to dampen vibration.

MISUMI also offers vibration damping and impact damping materials in the form of sheets.

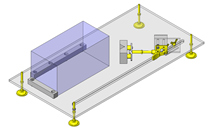

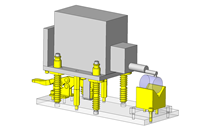

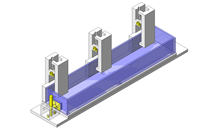

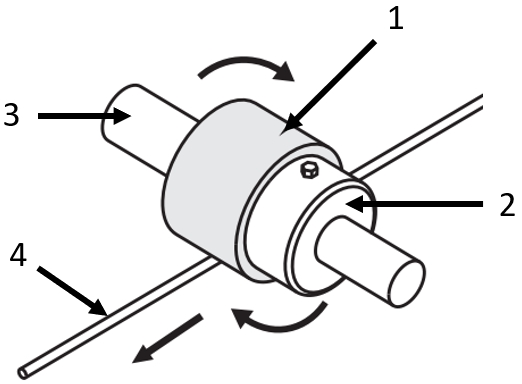

Application Examples - Polyurethane Rubber Washers

Application example: rubber roller

(1) Rubber sleeve, (2) Roller bearing, (3) Axles / Rotary Shafts, (4) Catch ropes

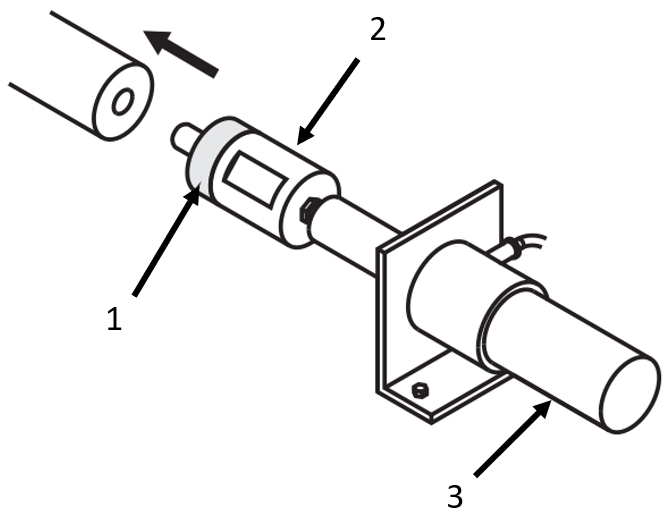

Application example: cylinder stopper buffer

(1) Rubber washer, (2) Floating joints, (3) Pneumatic cylinder

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number |

Standard Unit Price

| Minimum order quantity | Volume Discount | RoHS | Detailed Material | Hardness (shore, asker) | O.D. D (Ø) | Length L (mm) | Applicable Screw Size [M] | Collar Material | Collar Surface Treatment | H1 (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 60 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 80 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 100 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 60 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 80 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 100 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 60 | 30 ~ 150 | 10 ~ 12 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 80 | 40 ~ 200 | 12 ~ 16 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ether Polyurethane | Shore A90 | 100 | 40 ~ 200 | 12 ~ 16 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 60 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 80 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 100 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 60 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 80 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 100 | 40 ~ 200 | 12 ~ 16 | EN 1.1191 Equiv. | Electroless Nickel Plating | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 60 | 30 ~ 150 | 10 ~ 12 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 80 | 40 ~ 200 | 12 ~ 16 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A50 | 100 | 40 ~ 200 | 12 ~ 16 | EN 1.4301 Equiv. | Not Provided | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A70 | 15 | 25 ~ 80 | 3 ~ 4 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A70 | 20 | 25 ~ 80 | 4 ~ 5 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A70 | 25 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A70 | 30 | 25 ~ 80 | 6 ~ 8 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A70 | 40 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - | ||

- | 1 | 7 Days | 10 | [Standard Urethane] Ester Polyurethane | Shore A70 | 50 | 30 ~ 150 | 10 ~ 12 | EN 1.1191 Equiv. | Black Oxide | - |

Loading...

Back to the Category Disks/Sleeves (Rubber, Caoutchouc, Foam, Felt)

Technical Drawing - Polyurethane Rubber Washers

Open the technical drawing in the new window

Specification Tables - Polyurethane Rubber Washers

| Part Number | Selection | M | Urethane only H1 | With Collar | Unit Price | ||||||||||||||||||||||

| H2 | Collar No. | No Collar | With Collar | ||||||||||||||||||||||||

| Type | D | L | Urethane only | Black Oxide | Electroless Nickel Plating | EN 1.4301 Equiv. | |||||||||||||||||||||

| Standard Urethane | Abrasion Resistant | Heat Resistant | Standard Urethane | Abrasion Resistant | Heat Resistant | Standard Urethane | Standard Urethane | ||||||||||||||||||||

| AZX□K | AZEX□K | AZXHHK | AZX□C | AZEX□C | AZXHHC | AZX□M | AZX□S | ||||||||||||||||||||

| 12 | 12 | M3 | 5 | - | - | - | - | - | - | ||||||||||||||||||

| 15 | 12 | 15 | 5 | 3 | |||||||||||||||||||||||

| No Collar | With Collar | With Collar | With Collar | 15 | 20 | M4 | 4 | ||||||||||||||||||||

| Urethane only | Black Oxide | Electroless Nickel Plating | EN 1.4301 Equiv. | 20 | 20 | 25 | 7 | 7 | 4A | ||||||||||||||||||

| 20 | 25 | M5 | 5 | ||||||||||||||||||||||||

| AZXSK | AZXSC | AZXSM | AZXSS | ( | Standard | Shore A95 | ) | 25 | 20 | 25 | M6 | 8 | 8 | 6 | |||||||||||||

| AZXHK | AZXHC | AZXHM | AZXHS | ( | Standard | Shore A90 | ) | 20 | 25 | M8 | 6 | 8A | |||||||||||||||

| AZXMK | AZXMC | AZXMM | AZXMS | ( | Standard | Shore A70 | ) | 30 | 20 | 25 | 30 | M6 | 10 | 8 | 6 | ||||||||||||

| AZXLK | AZXLC | AZXLM | AZXLS | ( | Standard | Shore A50 | ) | 25 | 30 | 40 | M8 | 8 | |||||||||||||||

| AZEXHK | AZEXHC | ( | Abrasion Resistant | Shore A90 | ) | 40 | 30 | 40 | M10 | 12 | 10 | 10 | |||||||||||||||

| AZEXMK | AZEXMC | ( | Abrasion Resistant | Shore A70 | ) | 30 | 40 | 50 | M12 | 12 | |||||||||||||||||

| AZXHHK | AZXHHC | ( | Heat Resistant | Shore A90 | ) | 50 | 30 | 40 | M10 | 15 | 10 | ||||||||||||||||

| 40 | 50 | M12 | 12 | ||||||||||||||||||||||||

| 60 | 30 | 40 | M10 | 10 | |||||||||||||||||||||||

| 40 | 50 | M12 | 12 | ||||||||||||||||||||||||

■ L Configurable

| Part Number | L (1mm Increment) | M Selection | H1 1mm Increment | H2 Selectable | |||||||||

| Type | D | Urethane only | With Collar | ||||||||||

| 15 | 15~80 | 25~80 | M3 M4 | 5≤H1 | 5(M3)7(M4) | ||||||||

| No Collar | With Collar | With Collar | With Collar | 20 | M4 M5 | 7(M4 M5) | |||||||

| Urethane only | Black Oxide | Electroless Nickel Plating | EN 1.4301 Equiv. | 25 | M6 M8 | 8(M6 M8) | |||||||

| 30 | |||||||||||||

| AZXS | AZCS | AZCS-M | AZCS-S | ( | Standard | Shore A95 | ) | 40 | 25~150 | 30~150 | M10 M12 | 10(M10 M12) | |

| AZXH | AZCH | AZCH-M | AZCH-S | ( | Standard | Shore A90 | ) | 50 | |||||

| AZXM | AZCM | AZCM-M | AZCM-S | ( | Standard | Shore A70 | ) | 60 | |||||

| AZXL | AZCL | AZCL-M | AZCL-S | ( | Standard | Shore A50 | ) | 80 | 25~200 | 40~200 | M12 M16 | 10(M12) 15(M16) | |

| 100 | |||||||||||||

Basic information

| Shape | Counterbored | Material | Urethane |

|---|

Configure

Stock

-

- Show only stock items

Basic Attributes

-

Detailed Material

- Standard Urethane

- Heat Resistant Urethane

- Abrasion Resistant Urethane

- Standard Urethane

-

Hardness (shore, asker)

-

O.D. D(Ø)

-

Length L(mm)

-

Applicable Screw Size [M]

-

Collar Material

- EN 1.1191 Equiv.

- EN 1.4301 Equiv.

- No Collar

-

Collar Surface Treatment

- Black Oxide

- Electroless Nickel Plating

- Not Provided

-

H1(mm)

-

Type

- AZCH

- AZCH-M

- AZCH-S

- AZCL

- AZCL-M

- AZCL-S

- AZCM

- AZCM-M

- AZCM-S

- AZCS

- AZCS-M

- AZCS-S

- AZEXHC

- AZEXHK

- AZEXMC

- AZEXMK

- AZXH

- AZXHC

- AZXHHC

- AZXHHK

- AZXHK

- AZXHM

- AZXHS

- AZXL

- AZXLC

- AZXLK

- AZXLM

- AZXLS

- AZXM

- AZXMC

- AZXMK

- AZXMM

- AZXMS

- AZXS

- AZXSC

- AZXSK

- AZXSM

- AZXSS

-

Filter by CAD data type

- 2D

- 3D

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

What is Vulkollan?

-

Answer:

Vulkollan is a highly abrasion-resistant polyurethane rubber that has high wear resistance. It is one of the high-performance rubbers that has little pressure deformation and can withstand high impact forces. In addition, Vulkollan has a high tear strength. However, over time Vulkollan may change its colour, but without losing its mechanical properties.

-

Question:

Which rubber is resistant?

-

Answer:

Vulkollan is an abrasion-resistant material. It has an approx. six-fold higher abrasion resistance than conventional polyurethane materials. Vulkollan is particularly suitable for applications where high abrasion is expected.

-

Question:

Which rubber washer is oil-resistant?

-

Answer:

A rubber disc made of nitrile rubber (NBR) is highly resistant to various oils. This material is often used as a seal due to its good heat resistance and abrasion resistance.

-

Question:

Can a rubber sleeve be glued?

-

Answer:

A rubber sleeve or rubber disc can be stuck in or glued in. However, it must be ensured that the correct adhesive is selected in relation to the material of the elastomer. If this is not taken into account, the adhesive does not have the desired effect or even attack and degrade the elastomer. In addition, the adhesive should support the respective property of the material, e.g., antistatic or temperature resistance.

Complementary Products

Tech Support

- Technical Support

- Tel:+49 69 668173-0 / FAX:+49 69 668173-360

- Technical Inquiry