Round rod spacers / stainless steel, steel / black oxided, nickel-plated / external thread, internal thread / spanner flat

- Order quantities extended (D-JIT)

Part Number

Once your search is narrowed to one product,

the corresponding part number is displayed here.

- Drawing / Specifications

- 3D Preview 3D preview is available after complete configuration

- Part Numbers

- More Information

- Catalog

Back to the Category Distance elements (hexagonal, square, cylindrical)

Technical Drawing - Hexagonal Rods

Open the technical drawing in the new window

Available dimensions and tolerances can be found under the tab More information.

Basic Properties (e.g., material, hardness, coating, tolerance) - Hexagonal Rods

| Type | Material | Surface Treatment | |||||

| One End Threaded One End Tapped, Thread Length & Dia. Configurable | Both Ends Threaded | Both Ends Threaded, Thread Length & Dia. Configurable | |||||

| Standard | Wrench Flats | Standard | Wrench Flats | Standard | Wrench Flats | ||

| NETH | NETHS | NETL | NETLS | - | NETPS | EN 1.0038 Equiv. | - |

| ETKH | ETKHS | ETKL | ETKLS | - | ETKPS | Black Oxide | |

| PETH | PETHS | PETL | PETLS | PETP | PETPS | Electroless Nickel Plating | |

| SETH | SETHS | SETL | SETLS | SETP | SETPS | EN 1.4301 Equiv. | - |

Further specifications can be found under the tab More information.

Composition of a Product Code - Hexagonal Rods

| Part Number | - | L | - | F | - | G | - | SC | - | M | - | N |

| ETKH15 ETKLS12 NETPS12 | - - - | 210.5 300 300 | - - - | F40 F40 F40 | - | G20 | - - | SC150 SC150 | - - - | M6 M5 M8 | - - - | N8 N8 N8 |

Alterations - Hexagonal Rods

General Information - Hexagonal Rods

Selection details of spacers/spacers (hexagonal, square, cylindrical)

- Material: aluminum, steel, stainless steel, PMMA, PEEK

- Coatings: uncoated, burnished, chemically nickel-plated, anodized, chromated

- Basic shapes: hexagon, square, round

- End forms: straight, female thread, male thread, female thread with centering pin

- Outer diameter (round): 4 to 50 mm

- Spanner flat (hexagon, square): 4 to 32 mm

- Length: 5 to 800 mm

- Threads: M2 to M24

Description/Basics

Spacers are generally used as spacing connections. Due to their diversity, the wide range of design concepts can be realized with spacer bolts and practically every application can be realized using the appropriate spacer bolt.

The design and assembly of thin plates makes it extremely difficult to work with counterbores or internal threads. Therefore, spacer bolts are often used on plates, sheet metal or printed circuit boards (PCB).

The selectable assembly threads, the individually configurable length of the spacers, and the selectable length tolerance via the [LKC] option offer great design freedom compared to conventional mass-produced products. This advantage is particularly important if, for example, plates of different thicknesses or particularly thin plates are utilized.

For applications with particularly high positioning requirements, it is recommended to combine shim rings with a spacer. These can be configured in thicknesses from 0.01 to 1 mm and integrated as an additional compensating element.

The assembly of hexagonal spacers is particularly easy with the hex, since they can be held against one another with an open-ended spanner. With round spacer bolts, this can be realized with a spanner flat. The spacer bolts are also available with one-sided or two-sided internal thread (long nut). For precise positioning of a spacer bolt with an internal thread or external thread, MISUMI also offers a centering pin in the ISO tolerance h7.

This variety enables virtually barrier-free assembly of the components to be joined with screws, internal threads and external threads or nuts.

Application Examples - Hexagonal Rods

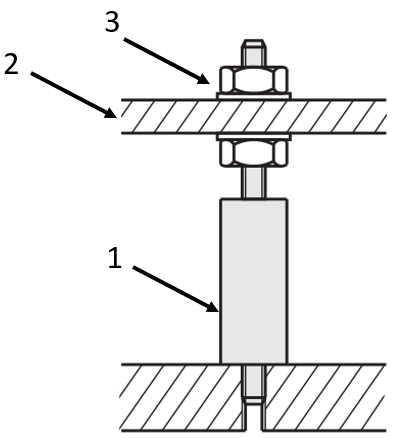

Application example: spacer bolt with external thread

(1) Spacer bolts with external thread on both sides, (2) mounting plate, (3) nut

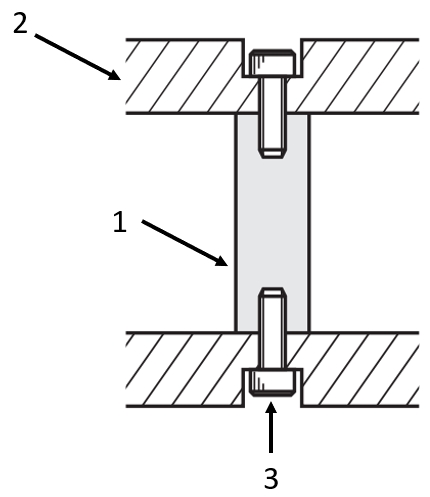

Application example: spacer bolts with internal thread

(1) Spacer with internal thread on both sides, (2) mounting plate, (3) screw

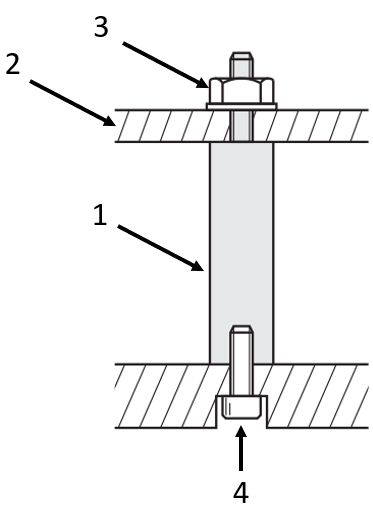

Application example: spacer with tappet

(1) Distance bolts with centering pin, (2) mounting plate, (3) nut, (4) screw

Application example: threaded spacer pin

(1) spacer bolts with internal thread and external thread, (2) mounting plate, (3) nut, (4) screw

Industrial Applications

Part Number:

- In order to open the 3D preview, the part number must be fixed.

3D preview is not available, because the part number has not yet been determined.

| Part Number | Minimum order quantity | Volume Discount | RoHS | O.D. D (φ) | Length L (mm) | Material | Surface Treatment | Thread Dia. M (mm) | Screw Dia. N (mm) | Screw Length F (mm) | Distance to Wrench Slot [SC] (mm) | Screw Length G (mm) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 6 Days | 10 | 5 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 2.6 ~ 3 | 2.6 ~ 3 | 5 ~ 25 | - | - | ||

| 1 | 6 Days | 10 | 6 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 3 ~ 4 | 3 ~ 4 | 5 ~ 30 | - | - | ||

| 1 | 6 Days | 10 | 8 | 20 ~ 150 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 5 | 4 ~ 5 | 8 ~ 40 | - | - | ||

| 1 | 6 Days | 10 | 10 | 20 ~ 350 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 6 | 4 ~ 6 | 8 ~ 45 | - | - | ||

| 1 | 6 Days | 10 | 12 | 25 ~ 400 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 5 ~ 8 | 5 ~ 8 | 10 ~ 55 | - | - | ||

| 1 | 6 Days | 10 | 15 | 30 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 10 | 6 ~ 10 | 12 ~ 60 | - | - | ||

| 1 | 6 Days | 10 | 20 | 40 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 12 | 6 ~ 12 | 15 ~ 75 | - | - | ||

| 1 | 6 Days | 10 | 25 | 55 ~ 600 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 16 | 6 ~ 16 | 20 ~ 80 | - | - | ||

| 1 | 6 Days | 10 | 30 | 65 ~ 700 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 20 | 6 ~ 20 | 25 ~ 90 | - | - | ||

| 1 | 6 Days | 10 | 5 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 2.6 ~ 3 | 2.6 ~ 3 | 5 ~ 25 | 0 ~ 42 | - | ||

| 1 | 6 Days | 10 | 6 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 3 ~ 4 | 3 ~ 4 | 5 ~ 30 | 0 ~ 42 | - | ||

| 1 | 6 Days | 10 | 8 | 20 ~ 150 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 5 | 4 ~ 5 | 8 ~ 40 | 0 ~ 142 | - | ||

| 1 | 6 Days | 10 | 10 | 20 ~ 350 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 6 | 4 ~ 6 | 8 ~ 45 | 0 ~ 342 | - | ||

| 1 | 6 Days | 10 | 12 | 25 ~ 400 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 5 ~ 8 | 5 ~ 8 | 10 ~ 55 | 0 ~ 390 | - | ||

| 1 | 6 Days | 10 | 15 | 30 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 10 | 6 ~ 10 | 12 ~ 60 | 0 ~ 490 | - | ||

| 1 | 6 Days | 10 | 20 | 40 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 12 | 6 ~ 12 | 15 ~ 75 | 0 ~ 490 | - | ||

| 1 | 6 Days | 10 | 25 | 55 ~ 600 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 16 | 6 ~ 16 | 20 ~ 80 | 0 ~ 590 | - | ||

| 1 | 6 Days | 10 | 30 | 65 ~ 700 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 20 | 6 ~ 20 | 25 ~ 90 | 0 ~ 685 | - | ||

| 1 | 6 Days | 10 | 5 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 2.6 ~ 3 | 2.6 ~ 3 | 5 ~ 25 | - | - | ||

| 1 | 6 Days | 10 | 6 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 3 ~ 4 | 3 ~ 4 | 5 ~ 30 | - | - | ||

| 1 | 6 Days | 10 | 8 | 20 ~ 150 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 5 | 4 ~ 5 | 8 ~ 40 | - | - | ||

| 1 | 6 Days | 10 | 10 | 20 ~ 350 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 6 | 4 ~ 6 | 8 ~ 45 | - | - | ||

| 1 | 6 Days | 10 | 12 | 25 ~ 400 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 5 ~ 8 | 5 ~ 8 | 10 ~ 55 | - | - | ||

| 1 | 6 Days | 10 | 15 | 30 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 10 | 6 ~ 10 | 12 ~ 60 | - | - | ||

| 1 | 6 Days | 10 | 20 | 40 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 12 | 6 ~ 12 | 15 ~ 75 | - | - | ||

| 1 | 6 Days | 10 | 25 | 55 ~ 600 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 16 | 6 ~ 16 | 20 ~ 80 | - | - | ||

| 1 | 6 Days | 10 | 30 | 65 ~ 700 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 20 | 6 ~ 20 | 20 ~ 90 | - | - | ||

| 1 | 6 Days | 10 | 5 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 2.6 ~ 3 | 2.6 ~ 3 | 5 ~ 25 | 0 ~ 42 | - | ||

| 1 | 6 Days | 10 | 6 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 3 ~ 4 | 3 ~ 4 | 5 ~ 30 | 0 ~ 42 | - | ||

| 1 | 6 Days | 10 | 8 | 20 ~ 150 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 5 | 4 ~ 5 | 8 ~ 40 | 0 ~ 142 | - | ||

| 1 | 6 Days | 10 | 10 | 20 ~ 350 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 6 | 4 ~ 6 | 8 ~ 45 | 0 ~ 342 | - | ||

| 1 | 6 Days | 10 | 12 | 25 ~ 400 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 5 ~ 8 | 5 ~ 8 | 10 ~ 55 | 0 ~ 390 | - | ||

| 1 | 6 Days | 10 | 15 | 30 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 10 | 6 ~ 10 | 12 ~ 60 | 0 ~ 490 | - | ||

| 1 | 6 Days | 10 | 20 | 40 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 12 | 6 ~ 12 | 15 ~ 75 | 0 ~ 490 | - | ||

| 1 | 6 Days | 10 | 25 | 55 ~ 600 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 16 | 6 ~ 16 | 20 ~ 80 | 0 ~ 590 | - | ||

| 1 | 6 Days | 10 | 30 | 65 ~ 700 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 20 | 6 ~ 20 | 25 ~ 90 | 0 ~ 685 | - | ||

| 1 | 6 Days | 10 | 5 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 2.6 ~ 3 | 2.6 ~ 3 | 5 ~ 25 | - | 5 ~ 25 | ||

| 1 | 6 Days | 10 | 6 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 3 ~ 4 | 3 ~ 4 | 5 ~ 30 | - | 5 ~ 30 | ||

| 1 | 6 Days | 10 | 8 | 20 ~ 150 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 5 | 4 ~ 5 | 8 ~ 40 | - | 8 ~ 40 | ||

| 1 | 6 Days | 10 | 10 | 20 ~ 350 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 6 | 4 ~ 6 | 8 ~ 45 | - | 8 ~ 45 | ||

| 1 | 6 Days | 10 | 12 | 25 ~ 400 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 5 ~ 8 | 5 ~ 8 | 10 ~ 55 | - | 10 ~ 55 | ||

| 1 | 6 Days | 10 | 15 | 30 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 10 | 6 ~ 10 | 12 ~ 60 | - | 12 ~ 60 | ||

| 1 | 6 Days | 10 | 20 | 40 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 12 | 6 ~ 12 | 15 ~ 75 | - | 15 ~ 75 | ||

| 1 | 6 Days | 10 | 25 | 55 ~ 600 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 16 | 6 ~ 16 | 20 ~ 80 | - | 20 ~ 80 | ||

| 1 | 6 Days | 10 | 30 | 65 ~ 700 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 20 | 6 ~ 20 | 25 ~ 90 | - | 25 ~ 90 | ||

| 1 | 6 Days | 10 | 5 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 2.6 ~ 3 | 2.6 ~ 3 | 5 ~ 25 | 0 ~ 42 | 5 ~ 25 | ||

| 1 | 6 Days | 10 | 6 | 15 ~ 50 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 3 ~ 4 | 3 ~ 4 | 5 ~ 30 | 0 ~ 42 | 5 ~ 30 | ||

| 1 | 6 Days | 10 | 8 | 20 ~ 150 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 5 | 4 ~ 5 | 8 ~ 40 | 0 ~ 142 | 8 ~ 40 | ||

| 1 | 6 Days | 10 | 10 | 20 ~ 350 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 4 ~ 6 | 4 ~ 6 | 8 ~ 45 | 0 ~ 342 | 8 ~ 45 | ||

| 1 | 6 Days | 10 | 12 | 25 ~ 400 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 5 ~ 8 | 5 ~ 8 | 10 ~ 55 | 0 ~ 390 | 10 ~ 55 | ||

| 1 | 6 Days | 10 | 15 | 30 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 10 | 6 ~ 10 | 12 ~ 60 | 0 ~ 490 | 12 ~ 60 | ||

| 1 | 6 Days | 10 | 20 | 40 ~ 500 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 12 | 6 ~ 12 | 15 ~ 75 | 0 ~ 490 | 15 ~ 75 | ||

| 1 | 6 Days | 10 | 25 | 55 ~ 600 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 16 | 6 ~ 16 | 20 ~ 80 | 0 ~ 590 | 20 ~ 80 | ||

| 1 | 6 Days | 10 | 30 | 65 ~ 700 | [Stainless Steel] EN 1.4301 Equiv. | Not Provided | 6 ~ 20 | 6 ~ 20 | 25 ~ 90 | 0 ~ 685 | 25 ~ 90 |

Loading...

Back to the Category Distance elements (hexagonal, square, cylindrical)

Technical Drawing - Hexagonal Rods

Open the technical drawing in the new window

Specification Tables - Hexagonal Rods

| Part Number | 0.5mm Increment | M Selection | N Selection | W | ℓ1 | A | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type | D | L | F | SC With Wrench Flats Only | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 15~50 | 5~25 | 0~42 | 2.6 | 3 | 2.6 | 3 | 4 | 8 | 1.0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 15~50 | 5~30 | 0~42 | 3 | 4 | 3 | 4 | 5 | 1.0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 20~150 | 8~40 | 0~142 | 4 | 5 | 4 | 5 | 7 | 1.6 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 20~350 | 8~45 | 0~342 | 4 | 5 | 6 | 4 | 5 | 6 | 8 | 2.0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | 25~400 | 10~55 | 0~390 | 5 | 6 | 8 | 5 | 6 | 8 | 10 | 10 | 2.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | 30~500 | 12~60 | 0~490 | 6 | 8 | 10 | 6 | 8 | 10 | 13 | 3.0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 40~500 | 15~75 | 0~490 | 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | 17 | 3.5 | ||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 | 55~600 | 20~80 | 0~590 | 6 | 8 | 10 | 12 | 16 | 6 | 8 | 10 | 12 | 16 | 22 | 4.0 | ||||||||||||||||||||||||||||||||||||||||||||||||

| 30 | 65~700 | 25~90 | 0~685 | 6 | 8 | 10 | 12 | 16 | 20 | 6 | 8 | 10 | 12 | 16 | 20 | 27 | 15 | 5.0 | |||||||||||||||||||||||||||||||||||||||||||||

| *35 | 80~800 | 30~100 | 0~785 | 8 | 10 | 12 | 16 | 20 | 24 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | 15 | 6.0 | |||||||||||||||||||||||||||||||||||||||||||||

| *40 | 80~900 | 35~110 | 0~880 | 10 | 12 | 16 | 20 | 24 | 10 | 12 | 16 | 20 | 24 | 36 | 20 | 6.0 | |||||||||||||||||||||||||||||||||||||||||||||||

| *50 | 80~1000 | 40~120 | 0~980 | 12 | 16 | 20 | 24 | 12 | 16 | 20 | 24 | 41 | 20 | 6.0 | |||||||||||||||||||||||||||||||||||||||||||||||||

■Both Ends Threaded, Thread Length & Dia. Configurable

| Part Number | 0.5mm Increment | M Selection | N Selection | W | ℓ1 | A | ||||||||||||||||||||||||

| Type | D | L | F | G | SC With Wrench Flats Only | |||||||||||||||||||||||||

| (Standard) EN 1.0038 Equiv. PETP EN 1.4301 Equiv. SETP (Wrench Flats) EN 1.0038 Equiv. NETPS ETKPS PETPS EN 1.4301 Equiv. SETPS | 5 | 15~50 | 5~25 | 5~25 | 0~42 | 2.6 | 3 | 2.6 | 3 | 4 | 8 | 1.0 | ||||||||||||||||||

| 6 | 15~50 | 5~30 | 5~30 | 0~42 | 3 | 4 | 3 | 4 | 5 | 1.0 | ||||||||||||||||||||

| 8 | 20~150 | 8~40 | 8~40 | 0~142 | 4 | 5 | 4 | 5 | 7 | 1.6 | ||||||||||||||||||||

| 10 | 20~350 | 8~45 | 8~45 | 0~342 | 4 | 5 | 6 | 4 | 5 | 6 | 8 | 2.0 | ||||||||||||||||||

| 12 | 25~400 | 10~55 | 10~55 | 0~390 | 5 | 6 | 8 | 5 | 6 | 8 | 10 | 10 | 2.5 | |||||||||||||||||

| 15 | 30~500 | 12~60 | 12~60 | 0~490 | 6 | 8 | 10 | 6 | 8 | 10 | 13 | 3.0 | ||||||||||||||||||

| 20 | 40~500 | 15~75 | 15~75 | 0~490 | 6 | 8 | 10 | 12 | 6 | 8 | 10 | 12 | 17 | 3.5 | ||||||||||||||||

| 25 | 55~600 | 20~80 | 20~80 | 0~590 | 6 | 8 | 10 | 12 | 16 | 6 | 8 | 10 | 12 | 16 | 22 | 4.0 | ||||||||||||||

| 30 | 65~700 | 25~90 | 25~90 | 0~685 | 6 | 8 | 10 | 12 | 16 | 20 | 6 | 8 | 10 | 12 | 16 | 20 | 27 | 15 | 5.0 | |||||||||||

| *35 | 80~800 | 30~100 | 30~100 | 0~785 | 8 | 10 | 12 | 16 | 20 | 24 | 8 | 10 | 12 | 16 | 20 | 24 | 30 | 15 | 6.0 | |||||||||||

| *40 | 80~900 | 35~110 | 35~110 | 0~880 | 10 | 12 | 16 | 20 | 24 | 10 | 12 | 16 | 20 | 24 | 36 | 20 | 6.0 | |||||||||||||

| *50 | 80~1000 | 40~120 | 40~120 | 0~980 | 12 | 16 | 20 | 24 | 12 | 16 | 20 | 24 | 41 | 20 | 6.0 | |||||||||||||||

L Dimension Tolerance

L 15 ~ 300 ±0.1

L300.5~ 600 ±0.3

L600.5~1000 ±0.4

Alterations - Hexagonal Rods

Basic information

| Scale | W/o Scale | Pilot (Concave-Convex at End) | Not Provided |

|---|

Configure

Basic Attributes

-

O.D. D(φ)

-

Length L(mm)

-

Surface Treatment

- Not Provided

- Black Oxide

- Electroless Nickel Plating

-

Thread Dia. M(mm)

-

Screw Dia. N(mm)

-

Screw Length F(mm)

-

Distance to Wrench Slot [SC](mm)

-

Screw Length G(mm)

-

Type

- ETKH

- ETKHS

- ETKL

- ETKLS

- ETKPS

- NETH

- NETHS

- NETL

- NETLS

- NETPS

- PETH

- PETHS

- PETL

- PETLS

- PETP

- PETPS

- SETH

- SETHS

- SETL

- SETLS

- SETP

- SETPS

-

Material

- Steel

- Stainless Steel

- Steel

-

Filter by CAD data type

- 2D

- 3D

Filter by standard shipping days

-

- All

- 6 Days or Less

Optional Attributes

- The specifications and dimensions of some parts may not be fully covered. For exact details, refer to manufacturer catalogs .

Frequently Asked Questions (FAQ)

-

Question:

Do you also have hollow spacers?

-

Answer:

Spacers or spacer bolts are generally made of solid material. However, if a hollow spacer is required, MISUMI also offers spacer sleeves. These are configurable like the spacers and can be adapted to the required dimensions. For precise distance, we recommend selecting simultaneous grinding spacer sleeves.

-

Question:

Are the spacers stainless?

-

Answer:

The spacers and spacer bolts can be selected in stainless steel and in steel with surface coating. To select the coating, the spacers are available in burnished, chemically nickel-plated, clear anodized, chromated. Thus, depending on the application, the spacer bolts are protected against corrosion.

-

Question:

Do you have spacer bolts with an undercut?

-

Answer:

MISUMI offers an additional option [FC] the spacer bolts for an undercut. With this option, a cutout is added to the external thread of the spacer bolt. The dimensions of the cutout can be found in the overview as a PDF.