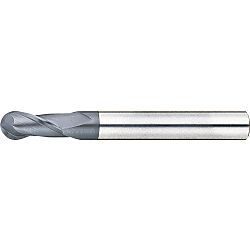

XAL Series Carbide Ball End Mill, 2-Flute / Regular Model

Rysunek konturowy

Szczegółowe informacje

Podstawowe informacje

The regular flute length type is introduced in the low-price and popular XAL balls

Specyfikacja i cena

Specifications

| Model Number | Shank Diameter d | Blade Length ℓ | Flute Diameter D | Overall Length L | Figure | ||

| Tip R | Shank Diameter d | ||||||

| XAL-BEM2R | 0.2 | - | 4 | 1.5 | 0.4 | 50 | 1 |

| 0.3 | - | 4 | 1.8 | 0.6 | 50 | 1 | |

| 0.4 | - | 4 | 2.4 | 0.8 | 50 | 1 | |

| 0.5 | - | 4 | 3 | 1 | 50 | 1 | |

| 0.5 | 6 | 6 | 3 | 1 | 50 | 1 | |

| 0.6 | - | 4 | 3.6 | 1.2 | 50 | 1 | |

| 0.75 | - | 4 | 4.5 | 1.5 | 50 | 1 | |

| 1 | - | 4 | 6 | 2 | 50 | 1 | |

| 1 | 6 | 6 | 6 | 2 | 50 | 1 | |

| 1.25 | - | 4 | 6 | 2.5 | 50 | 1 | |

| 1.5 | - | 4 | 8 | 3 | 60 | 1 | |

| 1.5 | 6 | 6 | 8 | 3 | 60 | 1 | |

| 2 | - | 6 | 12 | 4 | 70 | 1 | |

| 2.5 | - | 6 | 15 | 5 | 80 | 1 | |

| 3 | - | 6 | 18 | 6 | 90 | 2 | |

| 4 | - | 8 | 24 | 8 | 100 | 2 | |

| 5 | - | 10 | 30 | 10 | 100 | 2 | |

| 6 | - | 12 | 36 | 12 | 110 | 2 | |

| 8 | - | 16 | 48 | 16 | 140 | 2 |

Funkcje i przykłady użycia

More Information

● The XAL series exhibits stable wear-resistant performance when milling mild steel.

● It delivers high cost performance for pre-hardened steel, aluminum, and copper alloys.

● The XAL coating with excellent lubricity delivers stable wear-resistant performance, especially when milling mild steel, giving improved shape accuracy to the machined objects.

[ ! ]The XAL coating does not have conductive properties. Cannot be used with conduction model tool setters.